- Categories

-

- Carbon Steel

- »Seamless Steel Pipe

- »02API Line pipe

- »03Weld Steel Pipe

- »04_Square pipe

- »05_Ductile Iron pipe

- »06_Carbon Steel Sheet

- »07_Carbon Steel Coil/Strip

- »08_Steel Bar

- »09_Rebar

- »Steel Profile

- Galvanized Steel

- »Galvanized Steel Pipe

- »Galvanized Steel Sheet

- »Galvanized Steel Coil

- »Galvalume/Aluzinc Steel Coil

- »PPGI/PPGL

- »Corrugated Roofing Sheet

- »Galvanized Steel Wire

- »Galvanized Steel Profile

- Latest Products

-

-

PPGI/PPGL

-

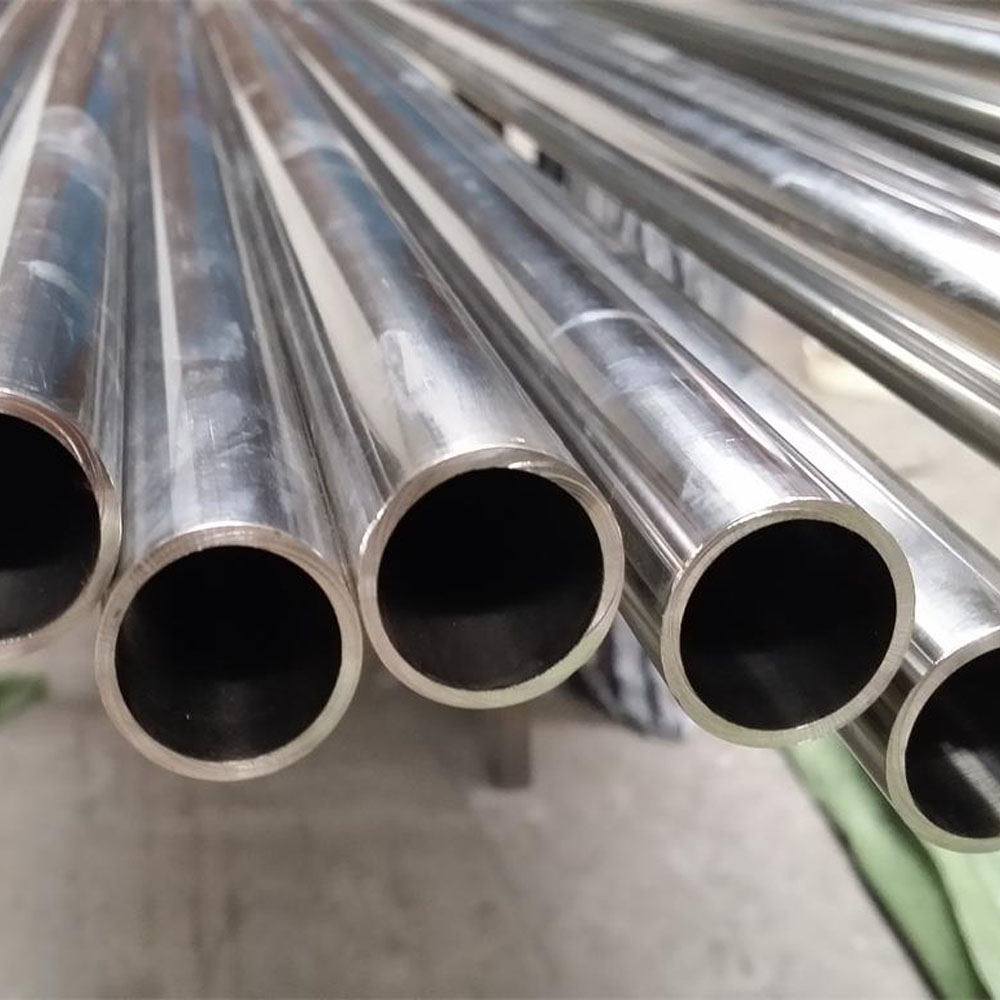

ASTM A321 TP321 seamless welded pipe and tube

-

ASTM B677 UNS NO8904 904L Pipe Tube

-

Hastelloy C-22 ASTM B474 UNS N06022 Alloy C-22 DIN 2.4602 EFW Welded Pipe

-

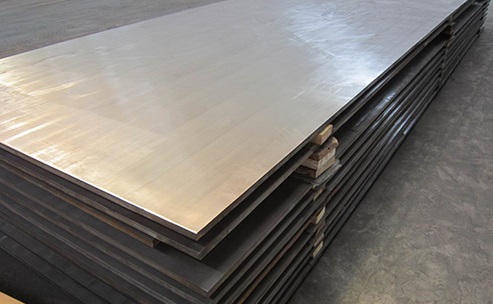

Duplex Steel N08904 Plate Sheet

-

Inconel 690 2.4642 Plate Sheet

-

ASTM B162 ASME SB162 UNS N02201 Alloy Steel Plate Sheet

-

ASTM A276 S30400 Round Bar

-

- Contact Us

-

Tel: 0086-17695531343

WhatsApp: 022-26819651

E-mail: sales@tsingshan-scaffold.com

Alloy 625 Plate

-

Type: Plate, Sheet, Strip, Coil

Length: 0-12m

Width: 0-2500mm

Thickness: 0.3-1200mm

Process: Hot/Cold Rolled

Surface: 1,2D,2B BA,3,4,6,7

ASME SB 168 Inconel 625 Sheet, Inconel 625 Plates Stockists, Inconel Alloy 625 Hot Rolled Plates, Inconel 625 Cold Rolled Plate, Inconel 625 Sheet and Plate Supplier, Inconel Alloy 625 Shim Sheets, Inconel 625 Coils, ASTM B168 Inconel 625 Sheet Exporter.

Alloy 625 Plate can be cold formed, hot worked, and machined through most standard methods. Hot forming should be done at temperature ranges of 1700 – 2150°F (927-1177°C), and care should be taken when cold working and machining, as Inconel 625 Plate work hardens more quickly than more traditional austenitic stainless steels. Recommend using rigid, powerful machines with sharp tooling at positive rake angles, with tools changed frequently to maintain sharpness. Heavy constant feeds are advised to maintain a positive cutting action with proper lubrication. Inconel Hot Rolled Plate may be welded through typical gas shielded processes.

Inconel 625 Cold Rolled Plate has three primary heat treatments – solution annealing at 2000-2200°F (1093 – 1204°C) with air or rapid quenching, annealing at 1600-1900°F (927-1038°C) with air or rapid quenching, and stress relieving at 1100-1600°F(593 – 900°C) with air quenching. Each process results in different characteristics, with the high temperature annealing used for applications above 1500°F where creep resistance is important. The medium temperature annealing provides optimal tensile and rupture properties up to 1900°F (1038°C), while the stress relieved state is recommended for applications under 1200°F (649°C), where maximum fatigue, hardness and yield strength are required.

Characteristics of Inconel 625

High strength and mechanical properties at both cryogenic and high temperatures.

High oxidation resistance at temperatures up to 1050°C.

High tensile, creep, and rupture strength.

Good resistance to oxidizing and reducing acids such as nitric, sulfuric, hydrochloric and phosphoric acid.

Virtually immune to chloride ion stress-corrosion cracking and pitting, making it ideal for marine applications.

Excellent weldabilty

ASTM B443 Alloy 625 Plate Imperial Dimensions

Plate Surface finish | Gauge (in) | Width (max in) |

2B – Cold rolled, heat treated, pickled, skin passed Plate | 10–24 | 72* |

2D – Cold rolled, heat treated, pickled plate | 12–24 | 60 |

BA Mexinox only | 18–28 | 48 |

Polished plate (not brushed) | 11–24 | 60 |

Temper rolled plate Mexinox only | 13–29 | 48 |

ASTM B443 625 Alloy Plate Metric Dimensions

Plate Surface finish | Thickness (mm) | Width (max mm) |

2B – Cold rolled, heat treated, pickled, skin passed plate | 0.25–8.0 | 2032 |

2D – Cold rolled, heat treated, pickled plate | 0.4–6.35 | 1524 |

2E – Cold rolled, heat treated, mechanically descaled plate | 0.4–8.0 | 2032 |

2R – Cold rolled, bright annealed plate | 0.25–3.5 | 1524 |

2H – Work hardened plate | 0.4–6.35 | 1524 |

Polished, brushed plate | 0.5–4.0 | 1524 |

Chemical Composition of ASTM B443 Alloy 625 Plate

Ni | Cr | Fe | Mo | Nb+Ta | C | Mn | Si | Ph | S | Al | Ti | Co | |

Min | Bal | 20 | - | 8 | 3.15 | - | - | - | - | - | - | - | - |

Max | - | 23 | 5 | 10 | 4.15 | 0.10 | 0.50 | 0.50 | 0.015 | 0.015 | 0.40 | 0.40 | 1.0 |

Send Inquiry

Copyright © 2024-2025 TSINGSHAN INDUSTRY(TIANJIN)CO.,LTD All Rights Reserved. 备案中... Privacy Policy

Home

Home Tel

Tel Email

Email Mobile phone

Mobile phone