- Categories

-

- Carbon Steel

- »Seamless Steel Pipe

- »02API Line pipe

- »03Weld Steel Pipe

- »04_Square pipe

- »05_Ductile Iron pipe

- »06_Carbon Steel Sheet

- »07_Carbon Steel Coil/Strip

- »08_Steel Bar

- »09_Rebar

- »Steel Profile

- Galvanized Steel

- »Galvanized Steel Pipe

- »Galvanized Steel Sheet

- »Galvanized Steel Coil

- »Galvalume/Aluzinc Steel Coil

- »PPGI/PPGL

- »Corrugated Roofing Sheet

- »Galvanized Steel Wire

- »Galvanized Steel Profile

- Latest Products

-

-

PPGI/PPGL

-

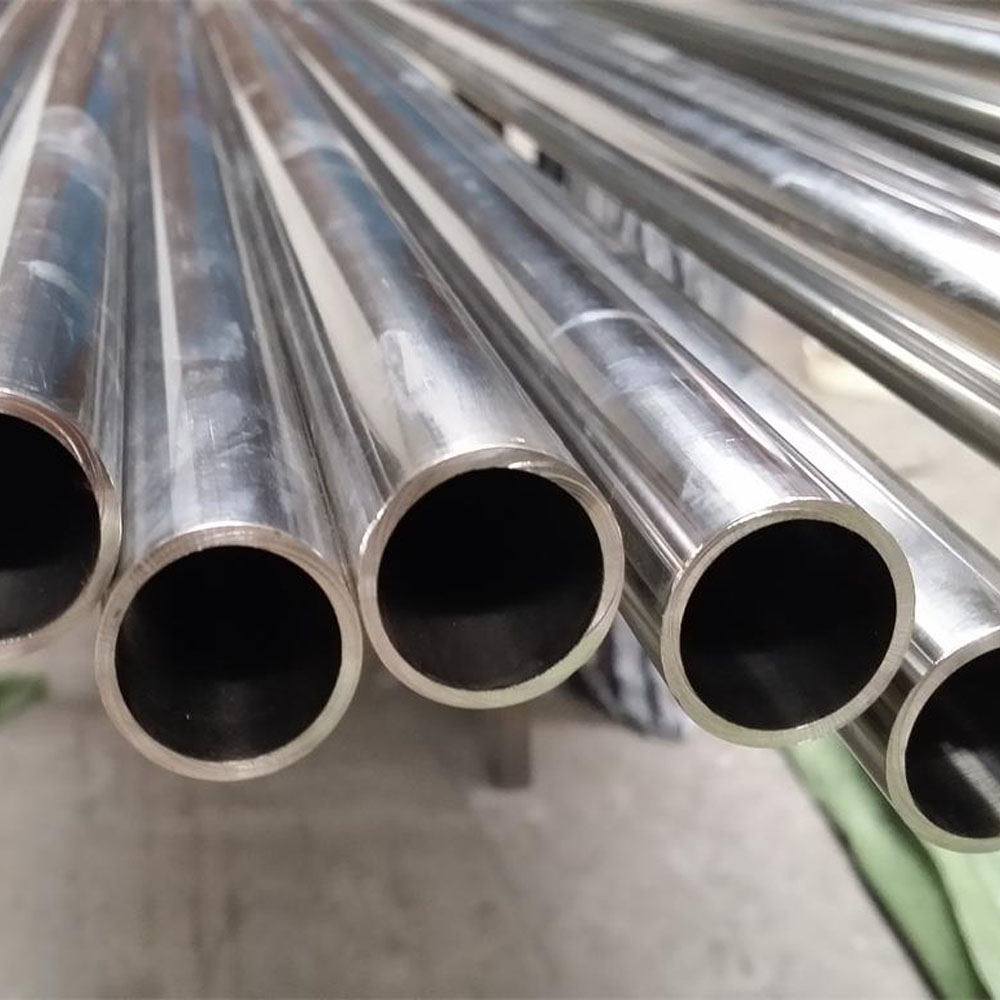

ASTM A321 TP321 seamless welded pipe and tube

-

ASTM B677 UNS NO8904 904L Pipe Tube

-

Hastelloy C-22 ASTM B474 UNS N06022 Alloy C-22 DIN 2.4602 EFW Welded Pipe

-

Duplex Steel N08904 Plate Sheet

-

Inconel 690 2.4642 Plate Sheet

-

ASTM B162 ASME SB162 UNS N02201 Alloy Steel Plate Sheet

-

ASTM A276 S30400 Round Bar

-

- Contact Us

-

Tel: 0086-17695531343

WhatsApp: 022-26819651

E-mail: sales@tsingshan-scaffold.com

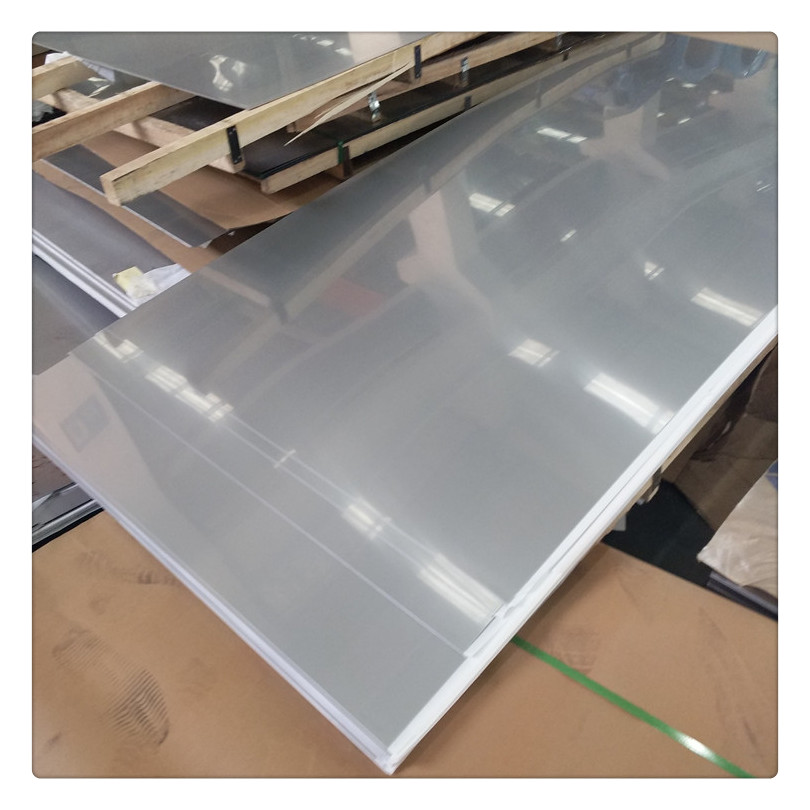

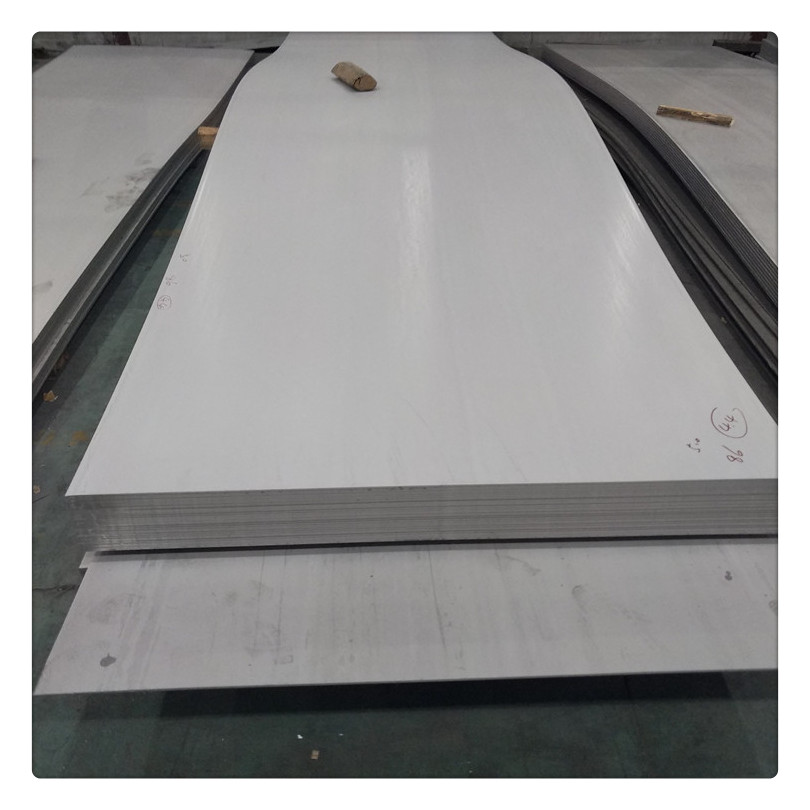

ASTM A240 316Ti Plate 6MM

-

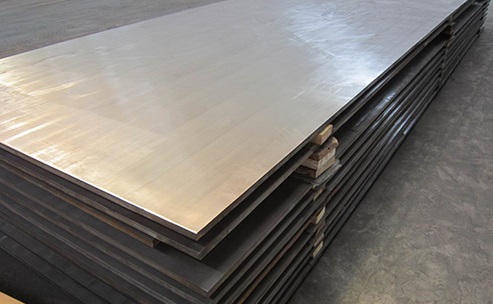

Type: Plate, Sheet, Strip, Coil

Length: 0-12m

Width: 0-2500mm

Thickness: 0.3-1200mm

Process: Hot/Cold Rolled

Surface: 1,2D,2B BA,3,4,6,7

ASTM A240 316Ti Plate, ASTM A240 SS 316Ti Plates Exporter, SS 316Ti 2D Finish Plates Supplier, Stainless Steel 316Ti 2B Finish Plates, SS 316Ti Export Polish Plates Stockists.

The titanium carbo-nitrides particles in SS 316Ti Plates can result in 'comet-tail' streaks on the polished surface as they are dragged out during polishing. The austenitic structure of ASTM A240 316Ti Plates gives excellent toughness, even at cryogenic temperatures. Note that this is due, in part, to the requirement that austenitic 316Ti Stainless Steel Sheets used at 1000 Degree F or higher must have 0.04 % minimum carbon.

The ASTM A240 316Ti Plates are more resistant to general corrosion and pitting/crevice corrosion than the conventional chromium-nickel austenitic stainless steels such as 304. ASTM A240 SS 316Ti Plates also offer higher creep, stress-rupture and tensile strength at elevated temperature. Resistance to sensitisation is achieved in SS 316Ti 2D Finish Plates with titanium additions to stabilise the structure against chromium carbide precipitation, which is the source of sensitisation. If filler metal must be used for welding 316Ti Stainless Steel Plates, it is advisable to utilize the low carbon Types 316Ti filler metals. Fabrication of all 316Ti Stainless Steel Coils should be done only with tools dedicated to stainless steel materials, where tooling and work surfaces must be thoroughly cleaned before use. Because stainless steel is more resistant to corrosion, our products like Stainless Steel 316Ti 2B Finish Plates far outlast carbon steel alternatives.

Chemical Composition:

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Fe |

| SS 316TI | 0.08 max | 2.0 max | 0.75 max | 0.045 max | 0.030 max | 16.00 - 18.00 | 2.00 - 3.00 | 10.00 - 14.00 | 68.395 min68.395 min |

Mechanical Properties:

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1399 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35% |

Send Inquiry

Copyright © 2024-2025 TSINGSHAN INDUSTRY(TIANJIN)CO.,LTD All Rights Reserved. 备案中... Privacy Policy

Home

Home Tel

Tel Email

Email Mobile phone

Mobile phone