Your Location:

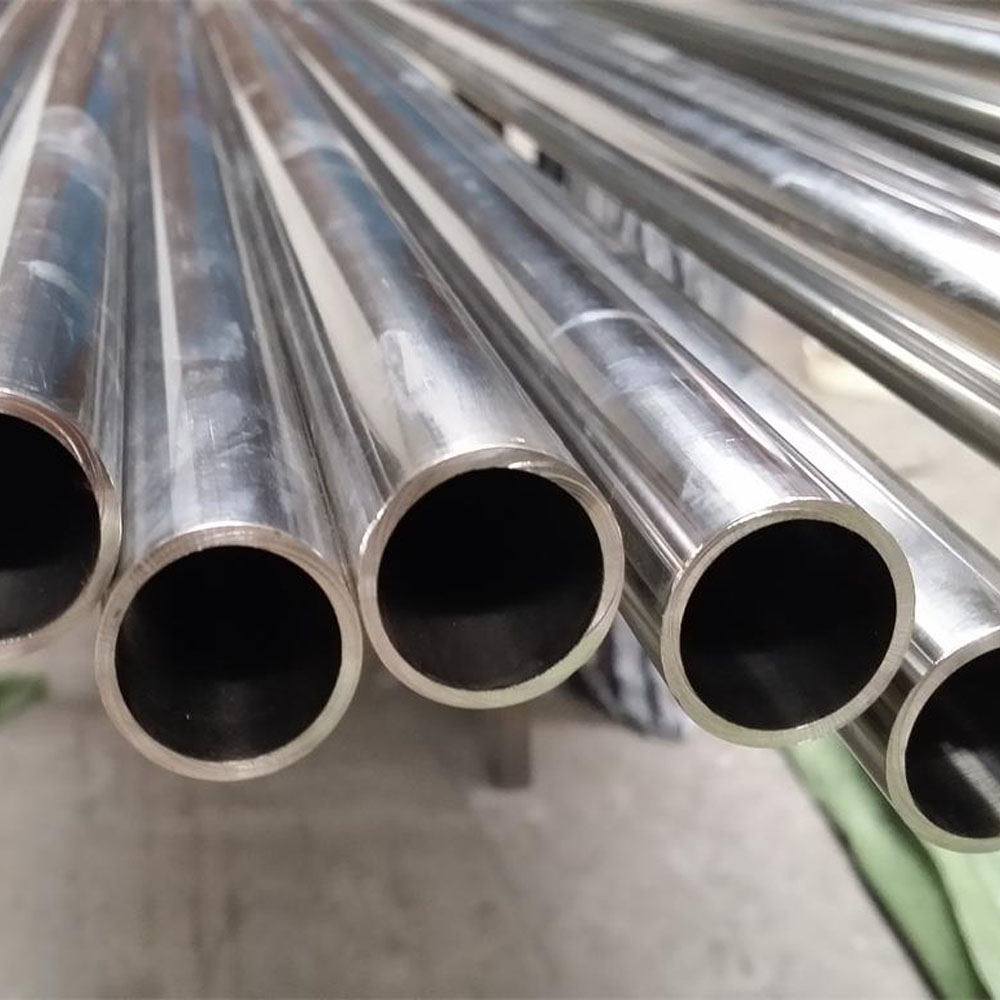

HOME >> PRODUCTS >> Carbon Steel >> Seamless Steel Pipe>>API5L GR.B pipe

- Categories

-

- Carbon Steel

- »Seamless Steel Pipe

- »02API Line pipe

- »03Weld Steel Pipe

- »04_Square pipe

- »05_Ductile Iron pipe

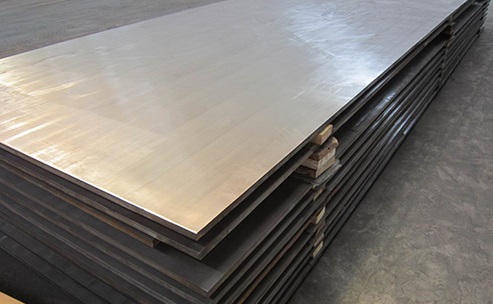

- »06_Carbon Steel Sheet

- »07_Carbon Steel Coil/Strip

- »08_Steel Bar

- »09_Rebar

- »Steel Profile

- Galvanized Steel

- »Galvanized Steel Pipe

- »Galvanized Steel Sheet

- »Galvanized Steel Coil

- »Galvalume/Aluzinc Steel Coil

- »PPGI/PPGL

- »Corrugated Roofing Sheet

- »Galvanized Steel Wire

- »Galvanized Steel Profile

- Latest Products

-

-

PPGI/PPGL

-

ASTM A321 TP321 seamless welded pipe and tube

-

ASTM B677 UNS NO8904 904L Pipe Tube

-

Hastelloy C-22 ASTM B474 UNS N06022 Alloy C-22 DIN 2.4602 EFW Welded Pipe

-

Duplex Steel N08904 Plate Sheet

-

Inconel 690 2.4642 Plate Sheet

-

ASTM B162 ASME SB162 UNS N02201 Alloy Steel Plate Sheet

-

ASTM A276 S30400 Round Bar

-

- Contact Us

-

Tel: 0086-17695531343

WhatsApp: 022-26819651

E-mail: sales@tsingshan-scaffold.com

API5L GR.B pipe

-

Chemical requirements Chemical Composition for PSL 1 pipe with t ≤ 0.984” Chemical Composition for PSL 2 pipe with t ≤ 0.984” Mechanical properties

Chemical requirements

Chemical Composition for PSL 1 pipe with t ≤ 0.984”

| Steel Grade | Mass fraction, % based on heat and product analyses a,g | ||||||

|---|---|---|---|---|---|---|---|

| C | Mn | P | S | V | Nb | Ti | |

| max b | max b | max | max | max | max | max | |

| Seamless Pipe | |||||||

| A | 0.22 | 0.9 | 0.3 | 0.3 | – | – | – |

| B | 0.28 | 1.2 | 0.3 | 0.3 | c,d | c,d | d |

| X42 | 0.28 | 1.3 | 0.3 | 0.3 | d | d | d |

| X46 | 0.28 | 1.4 | 0.3 | 0.3 | d | d | d |

| X52 | 0.28 | 1.4 | 0.3 | 0.3 | d | d | d |

| X56 | 0.28 | 1.4 | 0.3 | 0.3 | d | d | d |

| X60 | 0.28 e | 1.40 e | 0.3 | 0.3 | f | f | f |

| X65 | 0.28 e | 1.40 e | 0.3 | 0.3 | f | f | f |

| X70 | 0.28 e | 1.40 e | 0.3 | 0.3 | f | f | f |

| Welded Pipe | |||||||

| A | 0.22 | 0.9 | 0.3 | 0.3 | – | – | – |

| B | 0.26 | 1.2 | 0.3 | 0.3 | c,d | c,d | d |

| X42 | 0.26 | 1.3 | 0.3 | 0.3 | d | d | d |

| X46 | 0.26 | 1.4 | 0.3 | 0.3 | d | d | d |

| X52 | 0.26 | 1.4 | 0.3 | 0.3 | d | d | d |

| X56 | 0.26 | 1.4 | 0.3 | 0.3 | d | d | d |

| X60 | 0.26 e | 1.40 e | 0.3 | 0.3 | f | f | f |

| X65 | 0.26 e | 1.45 e | 0.3 | 0.3 | f | f | f |

| X70 | 0.26e | 1.65 e | 0.3 | 0.3 | f | f | f |

| a. Cu ≤ = 0.50% Ni; ≤ 0.50%; Cr ≤ 0.50%; and Mo ≤ 0.15%, b. For each reduction of 0.01% below the specified maximum concentration for carbon, an increase of 0.05% above the specified maximum concentration for Mn is permissible, up to a maximum of 1.65% for grades ≥ L245 or B, but ≤ L360 or X52; up to a maximum of 1.75% for grades > L360 or X52, but < L485 or X70; and up to a maximum of 2.00% for grade L485 or X70., c. Unless otherwise agreed NB + V ≤ 0.06%, d. Nb + V + TI ≤ 0.15%, e. Unless otherwise agreed., f. Unless otherwise agreed, NB + V = Ti ≤ 0.15%, g. No deliberate addition of B is permitted and the residual B ≤ 0.001% | |||||||

Mechanical properties

| Pipe Grade | Tensile Properties – Pipe Body of SMLS and Welded Pipes PSL 1 | Seam of Welded Pipe | ||

|---|---|---|---|---|

| Yield Strength a | Tensile Strength a | Elongation | Tensile Strength b | |

| Rt0,5 PSI Min | Rm PSI Min | (in 2in Af % min) | Rm PSI Min | |

| A | 30,500 | 48,600 | c | 48,600 |

| B | 35,500 | 60,200 | c | 60,200 |

| X42 | 42,100 | 60,200 | c | 60,200 |

| X46 | 46,400 | 63,100 | c | 63,100 |

| X52 | 52,200 | 66,700 | c | 66,700 |

| X56 | 56,600 | 71,100 | c | 71,100 |

| X60 | 60,200 | 75,400 | c | 75,400 |

| X65 | 65,300 | 77,500 | c | 77,500 |

| X70 | 70,300 | 82,700 | c | 82,700 |

| Pipe Grade | Tensile Properties – Pipe Body of SMLS and Welded Pipes PSL 2 | Seam of Welded Pipe | |||||

|---|---|---|---|---|---|---|---|

| Yield Strength a | Tensile Strength a | Ratio a,c | Elongation | Tensile Strength d | |||

| Rt0,5 PSI Min | Rm PSI Min | R10,5IRm | (in 2in) | Rm (psi) | |||

| Af % | |||||||

| Minimum | Maximum | Minimum | Maximum | Maximum | Minimum | Minimum | |

| BR, BN,BQ,BM | 35,500 | 65,300 | 60,200 | 95,000 | 0.93 | f | 60,200 |

| X42,X42R,X2Q,X42M | 42,100 | 71,800 | 60,200 | 95,000 | 0.93 | f | 60,200 |

| X46N,X46Q,X46M | 46,400 | 76,100 | 63,100 | 95,000 | 0.93 | f | 63,100 |

| X52N,X52Q,X52M | 52,200 | 76,900 | 66,700 | 110,200 | 0.93 | f | 66,700 |

| X56N,X56Q,X56M | 56,600 | 79,000 | 71,100 | 110,200 | 0.93 | f | 71,100 |

| X60N,X60Q,S60M | 60,200 | 81,900 | 75,400 | 110,200 | 0.93 | f | 75,400 |

| X65Q,X65M | 65,300 | 87,000 | 77,600 | 110,200 | 0.93 | f | 76,600 |

| X70Q,X65M | 70,300 | 92,100 | 82,700 | 110,200 | 0.93 | f | 82,700 |

| X80Q,X80M | 80,.500 | 102,300 | 90,600 | 119,700 | 0.93 | f | 90,600 |

Previous:ASTM A106 GR.B Seamless Steel Pipe

Send Inquiry

Copyright © 2024-2025 TSINGSHAN INDUSTRY(TIANJIN)CO.,LTD All Rights Reserved. 备案中... Privacy Policy

Home

Home Tel

Tel Email

Email Mobile phone

Mobile phone