- Categories

-

- Carbon Steel

- »Seamless Steel Pipe

- »02API Line pipe

- »03Weld Steel Pipe

- »04_Square pipe

- »05_Ductile Iron pipe

- »06_Carbon Steel Sheet

- »07_Carbon Steel Coil/Strip

- »08_Steel Bar

- »09_Rebar

- »Steel Profile

- Galvanized Steel

- »Galvanized Steel Pipe

- »Galvanized Steel Sheet

- »Galvanized Steel Coil

- »Galvalume/Aluzinc Steel Coil

- »PPGI/PPGL

- »Corrugated Roofing Sheet

- »Galvanized Steel Wire

- »Galvanized Steel Profile

- Latest Products

-

-

PPGI/PPGL

-

ASTM A321 TP321 seamless welded pipe and tube

-

ASTM B677 UNS NO8904 904L Pipe Tube

-

Hastelloy C-22 ASTM B474 UNS N06022 Alloy C-22 DIN 2.4602 EFW Welded Pipe

-

Duplex Steel N08904 Plate Sheet

-

Inconel 690 2.4642 Plate Sheet

-

ASTM B162 ASME SB162 UNS N02201 Alloy Steel Plate Sheet

-

ASTM A276 S30400 Round Bar

-

- Contact Us

-

Tel: 0086-17695531343

WhatsApp: 022-26819651

E-mail: sales@tsingshan-scaffold.com

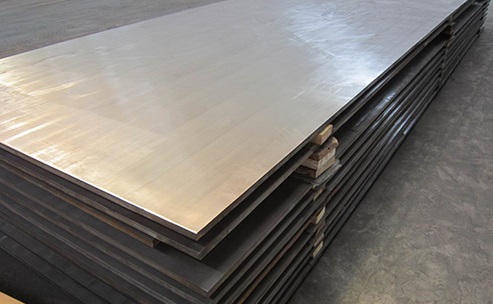

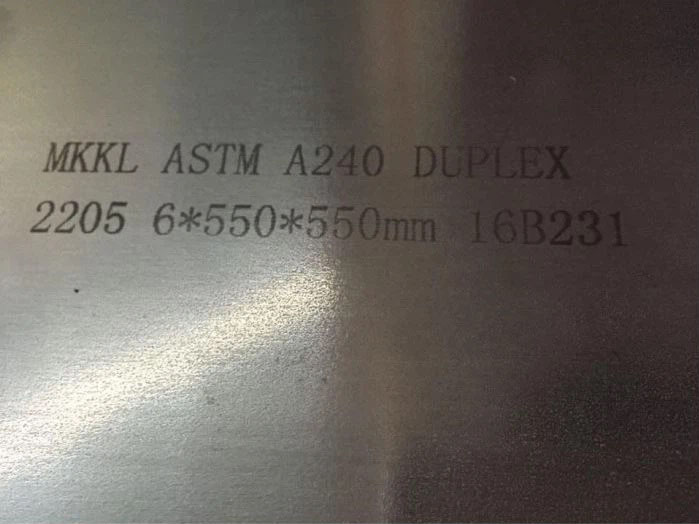

ASTM A240 UNS S31803 DUPLEX 2205 PLATE

-

Type: Plate, Sheet, Strip, Coil

Length: 0-12m

Width: 0-2500mm

Thickness: 0.3-1200mm

Process: Hot/Cold Rolled

Surface: 1,2D,2B BA,3,4,6,7

ASTM A240 UNS S31803 Duplex 2205 Plate is made up of a combination of austenitic and ferritic stainless steel grades, it adheres to stanard ASTM A240/A240M ASME SA240/SA240M - Specification for Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip for Pressure Vessels and for General Applications

Standard ASTM,AISI, AMS,MLS,EN,JIS,DIN,GOST Thickness 1.2-100mm Width 1000-1500mm Length 1000-6000mm Surface 2B, No.3, No.4, HL, BA, 8K Manufacturing process Hot rolled, cold rolled Duplex Steel SAF 2205/UNS S31803, SAF 2507/UNS S32750, S32760, S31200, S39277, S32520, S32205, S32250, N08904/1.4539, 254SMO/S31254/1.4574, 17-4PH/S17400/1.4548, 724L, 316Lmod/1.4435, 725LN/310MoLN Packing Bubble bag and plywood pallet or according to the customers' requirements. The inner size of container is below: 20ft GP: 5.8m(length) x

2.13m(width) x 2.18m(high) about 24-26CBM 40ft GP: 11.8m(length) x

2.13m(width) x 2.18m(high) about 54CBM 40ft HG: 11.8m(length) x

2.13m(width) x 2.72m(high) about 68CBM Application Petroleum/Power/Chemical/Construction/Gas/Metallurgy/Shipbuilding etc

The ASTM A240 UNS S31803 Duplex 2205 Plate is made up of the following composition:

Chromium (Cr) - 22% - 23%

Nickel (Ni) - 4.5% - 6.5%

Molybdenum (Mo) - 3% - 3.5%

Nitrogen (N) - 0.14% - 0.2%

Carbon (C) - Maximum 0.03%

Phosphorus (P) - Maximum 0.03%

Sulfur (S) - Maximum 0.02%

The ASTM A240 UNS S31803 Duplex 2205 Plate is manufactured using high-quality raw materials through various processes such as:

Hot rolling

Cold rolling

Annealing

Heat treatment

The ASTM A240 UNS S31803 Duplex 2205 Plate has the following physical properties:

Density - 7.8 g/cm3 or 0.28 lb/in3

Melting point - 1350 - 1450°C or 2460 - 2640°F

Elongation - Minimum 25%

Tensile strength - Minimum 655 MPa or 95 ksi

Yield strength - Minimum 450 MPa or 65 ksi

ASTM A240 UNS S31803 Duplex 2205 Application

Chemical processing industry

Oil and gas industry

Power generation industry

Marine industry

Pharmaceutical industry

Food and beverage industry

Petrochemical industry

Send Inquiry

Copyright © 2024-2025 TSINGSHAN INDUSTRY(TIANJIN)CO.,LTD All Rights Reserved. 备案中... Privacy Policy

Home

Home Tel

Tel Email

Email Mobile phone

Mobile phone