- Categories

-

- Carbon Steel

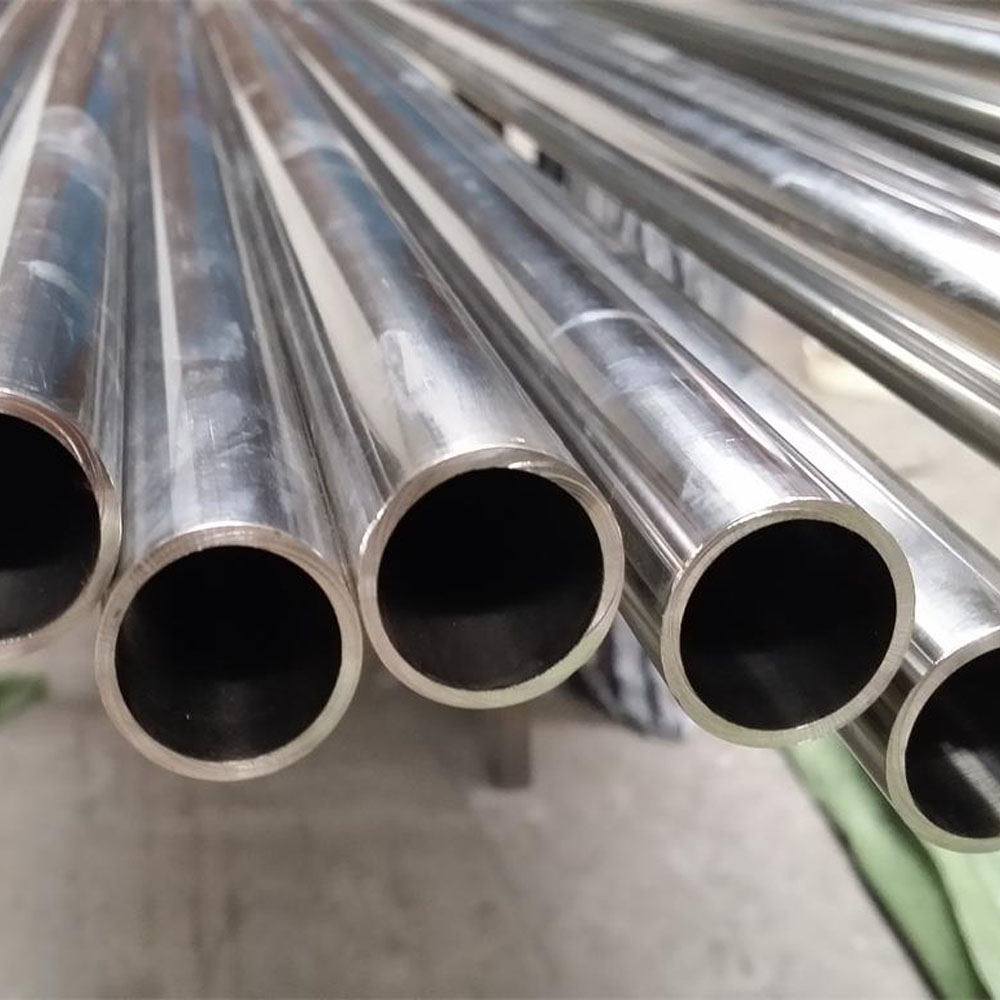

- »Seamless Steel Pipe

- »02API Line pipe

- »03Weld Steel Pipe

- »04_Square pipe

- »05_Ductile Iron pipe

- »06_Carbon Steel Sheet

- »07_Carbon Steel Coil/Strip

- »08_Steel Bar

- »09_Rebar

- »Steel Profile

- Galvanized Steel

- »Galvanized Steel Pipe

- »Galvanized Steel Sheet

- »Galvanized Steel Coil

- »Galvalume/Aluzinc Steel Coil

- »PPGI/PPGL

- »Corrugated Roofing Sheet

- »Galvanized Steel Wire

- »Galvanized Steel Profile

- Latest Products

-

-

PPGI/PPGL

-

ASTM A321 TP321 seamless welded pipe and tube

-

ASTM B677 UNS NO8904 904L Pipe Tube

-

Hastelloy C-22 ASTM B474 UNS N06022 Alloy C-22 DIN 2.4602 EFW Welded Pipe

-

Duplex Steel N08904 Plate Sheet

-

Inconel 690 2.4642 Plate Sheet

-

ASTM B162 ASME SB162 UNS N02201 Alloy Steel Plate Sheet

-

ASTM A276 S30400 Round Bar

-

- Contact Us

-

Tel: 0086-17695531343

WhatsApp: 022-26819651

E-mail: sales@tsingshan-scaffold.com

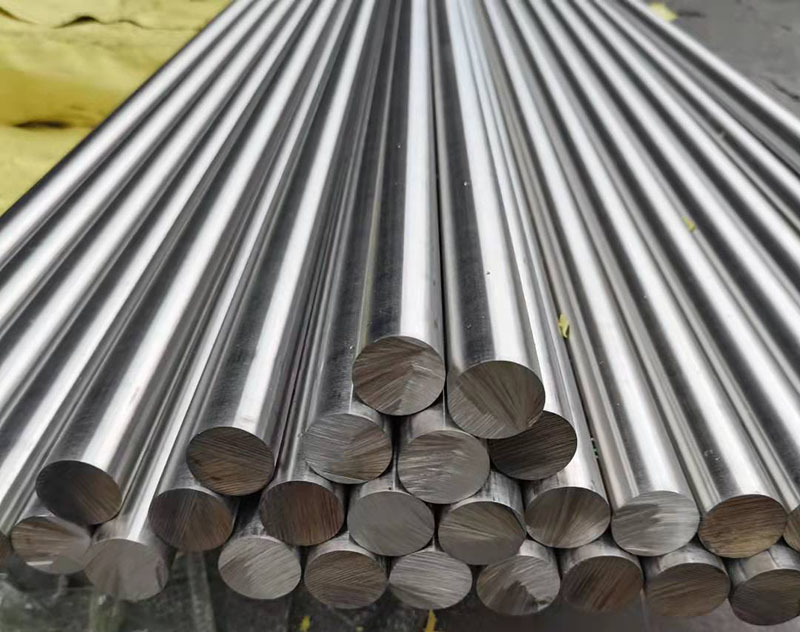

Monel K500 Rod Bar

-

UNS N05500/ W.Nr. 2.4375 Monel K500 nickel alloy steel round bar rod

UNS N05500/ W.Nr. 2.4375 Monel K500 nickel alloy steel round bar rod

Nickel Alloy 500 and Monel® K-500, commonly known as UNS N05500, is a nickel-copper based alloy which combines the excellent corrosion resistance of Nickel Alloy 400 with added advantages such as greater strength and hardness, making it superior to the other nickel-copper based alloys. This is achieved through the addition of titanium and aluminum which is added into the overall composition of the material. It has approximately twice the tensile strength and triple the yield strength of Nickel Alloy 400. This superior strength is maintained up to 1200° F, and conversely stays ductile and tough down to temperatures of – 400° F. Another advantage of Nickel Alloy 500 is that it stays non-magnetic at temperatures down to – 200° F which is ideal for applications where electronics are attached or in close proximity to the material where a magnetic field can be a disruption, such as downhole or tubing. Additional characteristics of Nickel Alloy 500 include spark resistance and outstanding corrosion resistance in a wide range of chemical and marine surroundings, including salts, alkalies (or acid-like substances), and non-oxidizing acids. NSA stocks a full range of Nickel Alloy 500 sizes and finishes; we receive our material from the mill age hardened (or aged) which has higher physicals than materials supplied in the annealed condition.

The increased

properties are obtained by adding aluminum and titanium to the

nickel-copper base, and by heating under controlled conditions so that

submicroscopic particles of Ni3 (Ti, Al) are precipitated throughout the

matrix. The thermal processing used to effect precipitation is commonly

called age hardening or aging.

Typical

applications for Monel Alloy K-500 products are chains and cables,

fasteners and springs for marine service; pump and valve components for

chemical processing; doctor blades and scrapers for pulp processing in

paper production; oil well drill collars and instruments, pump shafts

and impellers, non-magnetic housings, safety lifts and valves for oil

and gas production; and sensors and other electronic components.

MONEL

K500 is a age hardened alloy, whose basic composition makeup consists

of elements like Nickel & Copper. Which combines the corrosion

resistance of Alloy 400 with the high strength , fatigue resistance and

erosion resistance.MONEL K500 is a nickel-copper alloy, precipitation

hardenable through additions of aluminium and titanium. MONEL K500 has

excellent corrosion resistant characteristics. These characteristics are

similar to Monel 400.

Which

means that the ASTM B865 UNS N05500 Hex Bar

has enhanced strength, wear-resistance and hardness after precipitation

hardening when compared with 400.Before the precipitation hardening of

the ASTM B865 UNS N05500 Hex Bar , MONEL K500 can be strengthened

further by cold working.As compared to alloy 400, the ASTM B865 N05500

Flat Bar is known to have three times its yield strength and twice its

tensile strength .

Besides

having good corrosion resistance in an extensive range of marine and

chemical environments, the ASTM B865 Monel K500 Flat Bar

has Excellent mechanical properties from sub-zero temperatures up to

about 480C. Hence, their uses include Pumps and valves used in the

manufacture of perchloroethylene, chlorinated plastics, Propeller and

pump shafts.Typical application of the Monel K500 Bar that includes the

need of high tensile & yield strength and corrosion resistance are

pump shafts, impellers, valve components for ships and offshore drilling

towers, bolting, propeller shafts, oil well drill collars,

instrumentation components for oil and gas production.

Monel

500 bars are also especially well suited for applications in

centrifugal pumps in the marine industry due its high tensile strength

and low corrosion rates in high-velocity seawater.Because of its

non-magnetic, nature MONEL K500 can be used for nonmagnetic applications

. before aging, MONEL K500 should be annealed during welding following

which stress should be relieved.Although Monel K500 Round Bar could be

classified as difficult to machining, it can be noted that these alloys

can be machined using conventional production techniques at satisfactory rates.

While

machining these alloys tend to work harden rapidly. Thus, they generate

high heat during cutting operations, get welded to the cutting tool

surface and hence have a high resistance to metal removal because of

their high shear strengths.

The following are which should be taken into consideration during machining operations:

The capacity of the machine should be rigid and overpowered as much as possible.

The Monel K500 Bar and tool should be held rigid and needs to be sharp at all times.

Monel

K500 Rod most applications require high speed tools. High speed tools

along, with lower production rates are often recommended for

intermittent cuts for Monel 500 bars or rods.

ASTM B865 Monel Bar Condition

H&T Hardened and tempered. ANN Annealed PH Precipitation hardened.

Alloy K500 Bar Surface finish

CD Cold drawn P Polished BD Bright drawn SRE Slit rolled edge CG Centreless ground HF Hot finished CF Cold finished HRAP Hot rolled annealed and pickled P&T Peeled and turned RT Rough turned/peeled ST Smooth turned PR Peeled and reeled

Monel K500 Bar Mechanical Properties

Density Melting Point Tensile Strength Yield Strength (0.2%Offset) Elongation 8.44 g/cm3 1350 °C (2460 °F) Psi – 160000 , MPa – 1100 Psi – 115000 , MPa – 790 20 %

Monel K500 Round Bar Chemical Composition

Grade Ni Fe C Mn Si Cu Al S Ti Monel K500 63.0 min 0.5 – 2 0.25 max 1.5 max 0.5 max 27.0 – 33.0 2.3 – 3.15 0.010 max 0.35 – 0.85

AMS 4676 Monel K500 Bar Equivalent Grades

STANDARD | WERKSTOFF NR. | UNS |

|---|---|---|

Monel K500 | 2.4375 | N05500 |

Send Inquiry

Copyright © 2024-2025 TSINGSHAN INDUSTRY(TIANJIN)CO.,LTD All Rights Reserved. 备案中... Privacy Policy

Home

Home Tel

Tel Email

Email Mobile phone

Mobile phone