- Categories

-

- Carbon Steel

- »Seamless Steel Pipe

- »02API Line pipe

- »03Weld Steel Pipe

- »04_Square pipe

- »05_Ductile Iron pipe

- »06_Carbon Steel Sheet

- »07_Carbon Steel Coil/Strip

- »08_Steel Bar

- »09_Rebar

- »Steel Profile

- Galvanized Steel

- »Galvanized Steel Pipe

- »Galvanized Steel Sheet

- »Galvanized Steel Coil

- »Galvalume/Aluzinc Steel Coil

- »PPGI/PPGL

- »Corrugated Roofing Sheet

- »Galvanized Steel Wire

- »Galvanized Steel Profile

- Latest Products

-

-

PPGI/PPGL

-

ASTM A321 TP321 seamless welded pipe and tube

-

ASTM B677 UNS NO8904 904L Pipe Tube

-

Hastelloy C-22 ASTM B474 UNS N06022 Alloy C-22 DIN 2.4602 EFW Welded Pipe

-

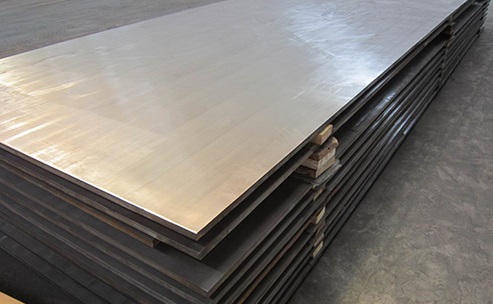

Duplex Steel N08904 Plate Sheet

-

Inconel 690 2.4642 Plate Sheet

-

ASTM B162 ASME SB162 UNS N02201 Alloy Steel Plate Sheet

-

ASTM A276 S30400 Round Bar

-

- Contact Us

-

Tel: 0086-17695531343

WhatsApp: 022-26819651

E-mail: sales@tsingshan-scaffold.com

ASTM A213 TP317L Seamless Tubes

-

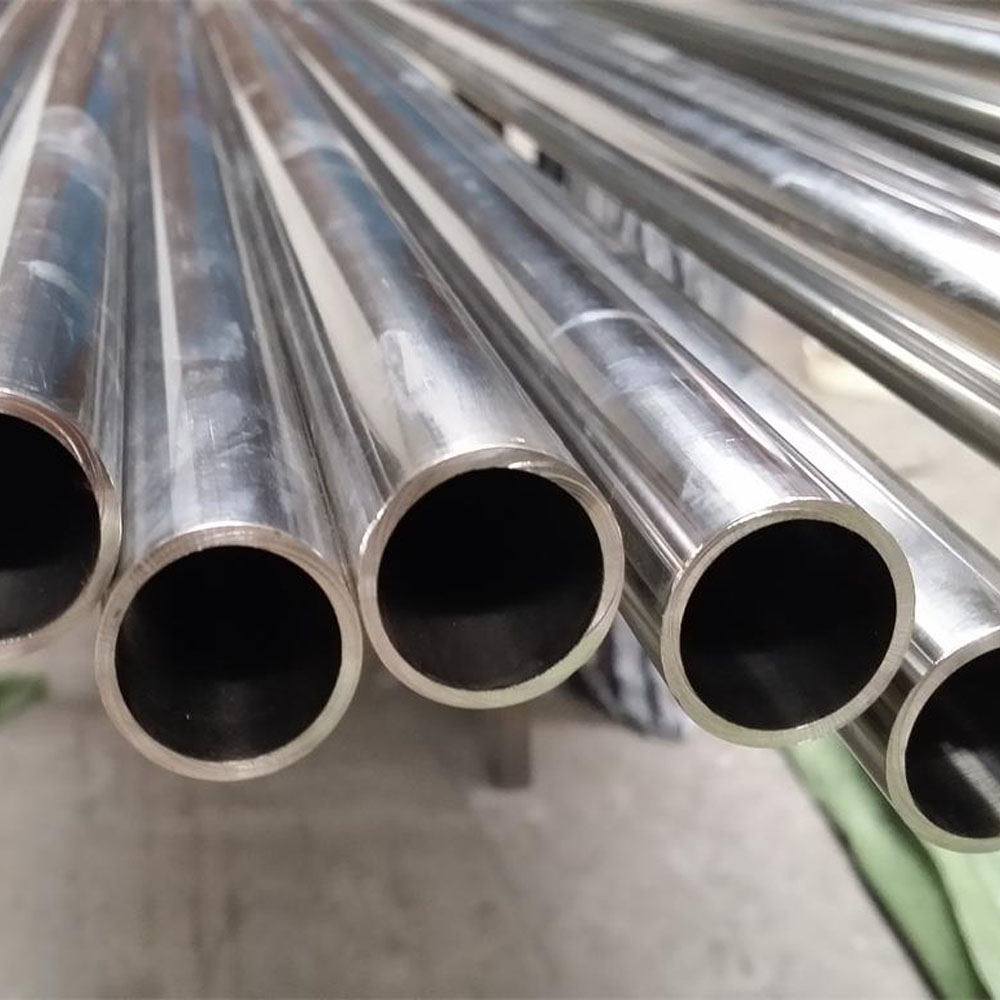

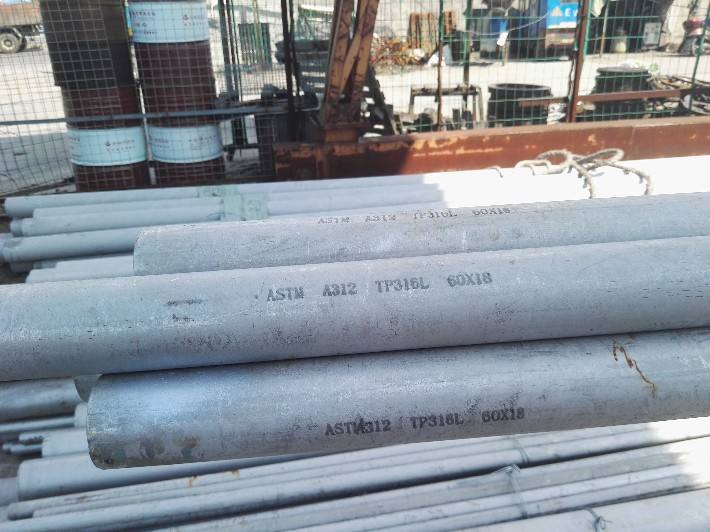

Type: Seamless, Welded

OD: 1/2"-48"

Thickness: SCH5-SCHXXS

Length: 0-12M, Customized

Process: Hot/Cold Rolled,Hot work,Cold drawn

ASTM A213 TP317L Seamless Tubes, SA 213 TP 317L Seamless Tube, 317L Stainless Steel Tubing, SA 213 TP 317L Pipe, SS 317L UNS S31700 ERW Tube, SS 317L UNS S31700 ERW Tube, SS 317L Welded Tubing, UNS S31700 Round Tubing.

ASTM A213 TP317L Seamless Tubes:

ASTM A213 TP317L Seamless Tube covered under specification ASTM A213 is designed to be a part of systems involving the use of either steel boiler, superheater, or heat-exchanger tubes. The L after grade 317 indicates that the SA 213 TP 317L is a lower carbon containing alloy.

Lowering the content of carbon in the production of grade SS 317L Welded Tubing is what ensures that the alloy does not become prone to intergranular corrosion, which in turn stems from the UNS S31700 Round Tubing being used at elevated temperatures especially in the chromium carbide precipitation range. Hence, the A213 TP317L Seamless Tube can be used in an as welded condition.

As opposed to grade 316L, the ASTM A213 TP317L Seamless Tube proves to be a valuable asset in strongly corrosive environments which contain compounds like sulfurous media, chlorides, and other halides with its resistance to corrosion.

SS UNS S31703 Tubing Mechanical Properties

Element | AISI 317L |

Density | 8.0 g/cm3 |

Melting Range | 1454 °C (2650 °F) |

Tensile Stress | Psi - 75000 , MPa - 515 |

Yield Stress (0.2%Offset) | Psi - 30000 , MPa - 205 |

Elongation | 35 % |

Hardness (Brinell) | - |

SA213 TP317L Tube Chemical Composition

SS 317L | Maximum |

Ni | 11 - 15 |

C | 0.035 Maximum |

Mn | 2 Maximum |

P | 0.040 Maximum |

S | 0.03 Maximum |

Si | 1 Maximum |

Cr | 18 - 20 |

Mo | 3 - 4 |

N | - |

Send Inquiry

Copyright © 2024-2025 TSINGSHAN INDUSTRY(TIANJIN)CO.,LTD All Rights Reserved. 备案中... Privacy Policy

Home

Home Tel

Tel Email

Email Mobile phone

Mobile phone