- Categories

-

- Carbon Steel

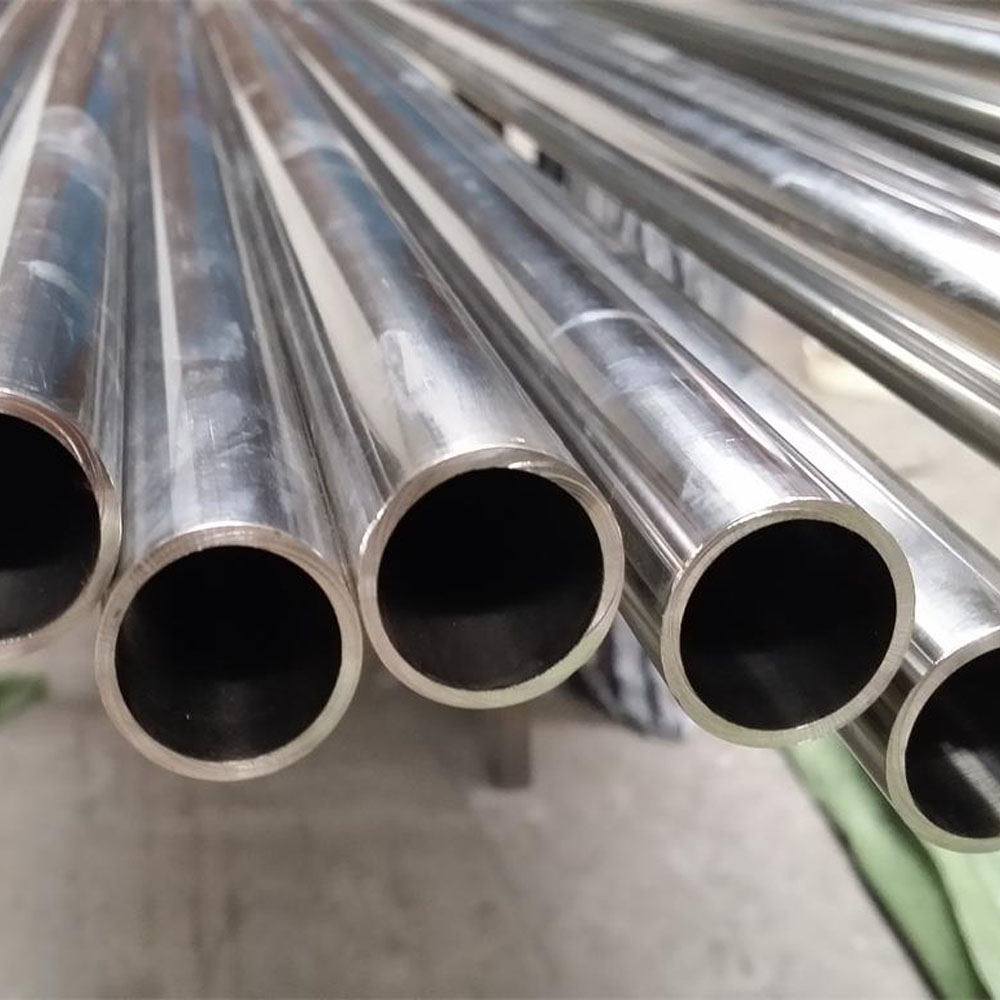

- »Seamless Steel Pipe

- »02API Line pipe

- »03Weld Steel Pipe

- »04_Square pipe

- »05_Ductile Iron pipe

- »06_Carbon Steel Sheet

- »07_Carbon Steel Coil/Strip

- »08_Steel Bar

- »09_Rebar

- »Steel Profile

- Galvanized Steel

- »Galvanized Steel Pipe

- »Galvanized Steel Sheet

- »Galvanized Steel Coil

- »Galvalume/Aluzinc Steel Coil

- »PPGI/PPGL

- »Corrugated Roofing Sheet

- »Galvanized Steel Wire

- »Galvanized Steel Profile

- Latest Products

-

-

PPGI/PPGL

-

ASTM A321 TP321 seamless welded pipe and tube

-

ASTM B677 UNS NO8904 904L Pipe Tube

-

Hastelloy C-22 ASTM B474 UNS N06022 Alloy C-22 DIN 2.4602 EFW Welded Pipe

-

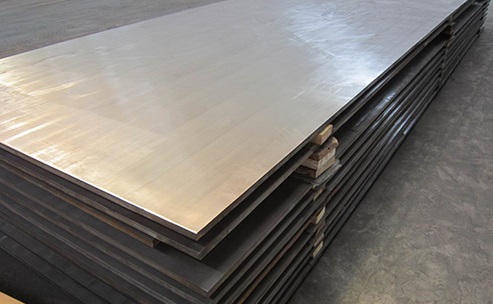

Duplex Steel N08904 Plate Sheet

-

Inconel 690 2.4642 Plate Sheet

-

ASTM B162 ASME SB162 UNS N02201 Alloy Steel Plate Sheet

-

ASTM A276 S30400 Round Bar

-

- Contact Us

-

Tel: 0086-17695531343

WhatsApp: 022-26819651

E-mail: sales@tsingshan-scaffold.com

Duplex Steel S31200 Plate Sheet

-

Type: Plate, Sheet, Strip, Coil

Length: 0-12m

Width: 0-2500mm

Thickness: 0.3-1200mm

Process: Hot/Cold Rolled

Surface: 1,2D,2B BA,3,4,6,7

Duplex steel S31200, also known as UNS S31200, is a grade of duplex stainless steel that has high strength and excellent resistance to corrosion. It isand it is widely used in various industrial applications such as chemical processing, offshore oil exploration, and gas processing.

Type | Plate, sheet, coil, strip |

Thickness | 1.2-100mm |

Width | 1000-1500mm |

Length | 1000-6000mm |

Surface | 2B, No.3, No.4, HL, BA, 8K |

Manufacturing process | Hot rolled, cold rolled |

Nickel Alloy steel: Inconel series Incoloy series Hastelloy series Monel series

| Alloy 200/Nickel 200/N02200/2.4066; Alloy 201/Nickel 201/N02201/2.4068; Alloy 400/Monel 400/N04400/NS111/2.4360; Alloy K-500/Monel K-500/N05500/2.4375; Alloy 600/Inconel 600/N06600/NS333/2.4816; Alloy 601/Inconel 601/N06601/2.4851; Alloy 625/Inconel 625/N06625/NS336/2.4856; Alloy 718/Inconel 718/N07718/GH169/GH4169/2.4668; Alloy 800/Incoloy 800/N08800/1.4876; Alloy 800H/Incoloy 800H/N08810/1.4876; Alloy 800HT/Incoloy 800HT/N08811/NS112/1.4876; Alloy 825/Incoloy 825/N08825/2.4858; Alloy 925/Incoloy 925/N09925; Alloy C-276/Hastelloy C-276/N10276/2.4819; Alloy C-4/Hastelloy C-4/N06455/NS335/2.4610; Alloy C-22/Hastelloy C-22/N06022/2.4602; Alloy 2000/Hastelloy C-2000/N06200/2.4675; Alloy B/Hastelloy B/NS321; Alloy B-2/Hastelloy B-2/N10665/NS322/2.4617; Alloy B-3/Hastelloy B-3/N10675/2.4600; Alloy X/HASTELLOY-X/N06002/2.4465; Alloy G-30/HASTELLOY G-30/N06030/2.4603; Alloy C-2000/HASTELLOY C-2000/N06200; Alloy X-750/INCONEL X-750/N07750/GH145/2.4669; Alloy 20/Carpenter 20Cb3/N08020/NS312/2.4660; Alloy 31/N08031/1.4562;Alloy 901/N09901/1.4898; Incoloy25-6Mo/N08925; Inconel 783;Alloy-6XN/N08367;Monel 30C Nimonic 80A/ 90/ 105 |

Packing | bubble bag and plywood pallet or according to the customers' requirements. The inner size of container is below: 20ft GP: 5.8m(length) x 2.13m(width) x 2.18m(high) about 24-26CBM 40ft GP: 11.8m(length) x 2.13m(width) x 2.18m(high) about 54CBM 40ft HG: 11.8m(length) x 2.13m(width) x 2.72m(high) about 68CBM |

Delivery time | 10-100 days depending on quantity |

Payment terms | T/T |

Shipment | FOB Tianjin/Shanghai, CIF, CFR, etc |

Application | Petroleum/Power/Chemical/Construction/Gas/Metallurgy/Shipbuilding etc |

Remarks | Other materials and drawings are available. |

Welcome to contact us ***************** Pipe Fittings Co.,Ltd (40 years manufacturing experience) | |

The process of manufacturing duplex steel S31200 plates/sheets involves hot and cold rolling, annealing, pickling, and finishing. The ingots of the steel are first heated to a temperature of 1150°C-1200°C and then hot rolled into plates or sheets. The hot-rolled plates/sheets are then cooled to room temperature, and their surface is treated using an acid solution to remove any oxides. The plates/sheets are then annealed in a controlled atmosphere to improve their mechanical properties and reduce their hardness. Finally, they are cold-rolled to achieve the desired dimensions and surface finish.

Duplex steel S31200 Chemical Composition:

- Carbon (C): 0.03% max

- Chromium (Cr): 22.0-23.0%

- Nickel (Ni): 4.50-6.50%

- Molybdenum (Mo): 3.00-3.50%

- Nitrogen (N): 0.14-0.20%

- Phosphorus (P): 0.030% max

- Sulfur (S): 0.020% max

- Silicon (Si): 1.00% max

- Manganese (Mn): 2.00% max

- Iron (Fe): balance

Duplex steel S31200 plates physical properties

- Density: 7.8 g/cm³

- Melting point: 1398-1446°C

- Thermal conductivity: 14.2 W/mK at 100°C

- Coefficient of thermal expansion: 13.7 µm/m°C at 20°C

- Specific heat capacity: 460 J/kg°C at 20°C

- Electrical resistivity: 74 µΩ·cm at 20°C

Duplex steel S31200 plates Application:

- Chemical processing: Duplex steel S31200 plates/sheets have

excellent corrosion resistance, making them suitable for use in chemical

processing plants. They are used to build tanks, pipework, and other

equipment that comes in contact with harsh chemicals.

- Offshore oil exploration: Duplex steel S31200 plates/sheets are used

in offshore platforms, drilling equipment, and pipelines due to their

high strength and corrosion resistance.

- Gas processing: Duplex steel S31200 plates/sheets are used to build

compressors, valves, and other equipment that is exposed to

high-pressure and corrosive gases.

- Structural applications: Duplex steel S31200 plates/sheets are used in

the construction industry to build bridges, tunnels, and other

structures due to their high strength and durability.

Duplex steel S31200 plates/sheets are a high-quality duplex stainless steel with a unique combination of austenitic and ferritic phases. They have excellent strength and corrosion resistance, making them ideal for use in various industrial applications. The manufacturing process of duplex steel S31200 plates/sheets involves hot and cold rolling, annealing, pickling, and finishing, resulting in a high-quality product that meets various standards. The chemical composition and physical properties of duplex steel S31200 plates/sheets are carefully balanced to provide optimal performance in different applications. Overall, duplex steel S31200 plates/sheets are an excellent choice for any application that requires high strength and corrosion resistance.

Send Inquiry

Copyright © 2024-2025 TSINGSHAN INDUSTRY(TIANJIN)CO.,LTD All Rights Reserved. 备案中... Privacy Policy

Home

Home Tel

Tel Email

Email Mobile phone

Mobile phone