- Categories

-

- Carbon Steel

- »Seamless Steel Pipe

- »02API Line pipe

- »03Weld Steel Pipe

- »04_Square pipe

- »05_Ductile Iron pipe

- »06_Carbon Steel Sheet

- »07_Carbon Steel Coil/Strip

- »08_Steel Bar

- »09_Rebar

- »Steel Profile

- Galvanized Steel

- »Galvanized Steel Pipe

- »Galvanized Steel Sheet

- »Galvanized Steel Coil

- »Galvalume/Aluzinc Steel Coil

- »PPGI/PPGL

- »Corrugated Roofing Sheet

- »Galvanized Steel Wire

- »Galvanized Steel Profile

- Latest Products

-

-

PPGI/PPGL

-

ASTM A321 TP321 seamless welded pipe and tube

-

ASTM B677 UNS NO8904 904L Pipe Tube

-

Hastelloy C-22 ASTM B474 UNS N06022 Alloy C-22 DIN 2.4602 EFW Welded Pipe

-

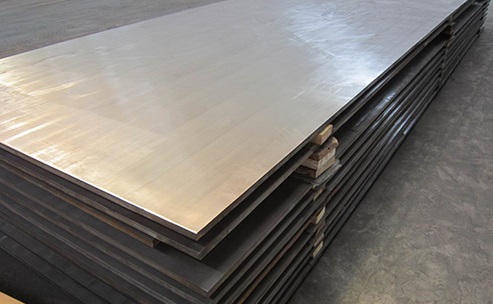

Duplex Steel N08904 Plate Sheet

-

Inconel 690 2.4642 Plate Sheet

-

ASTM B162 ASME SB162 UNS N02201 Alloy Steel Plate Sheet

-

ASTM A276 S30400 Round Bar

-

- Contact Us

-

Tel: 0086-17695531343

WhatsApp: 022-26819651

E-mail: sales@tsingshan-scaffold.com

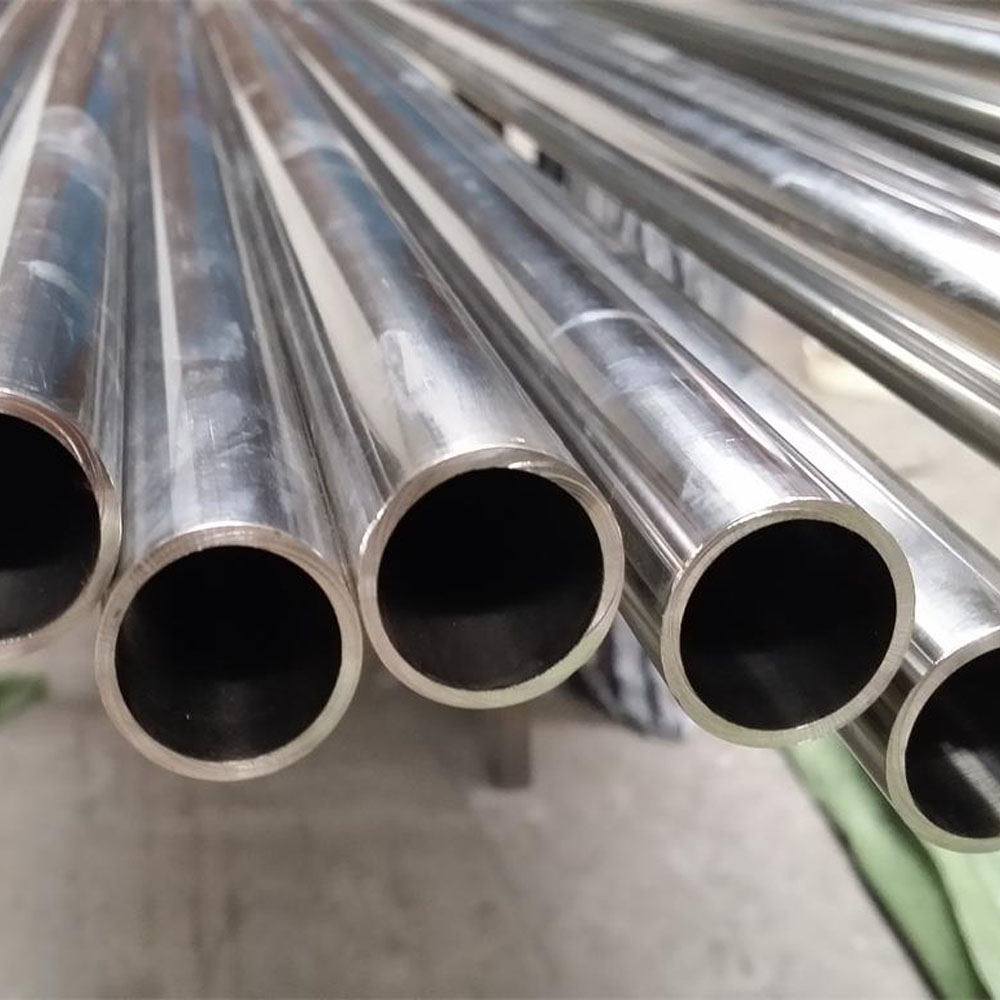

Nickel Alloy Pipe And Tube Hastelloy C276 C22 B2 With Good Price And High Purity

-

Type: Seamless, Welded

OD: 1/2"-48"

Thickness: SCH5-SCHXXS

Length: 0-12M, Customized

Process: Hot/Cold Rolled,Hot work,Cold drawn

Hastelloy Alloy C276 Pipes & Tubes, Latest Price of Hastelloy Alloy C22 Pipes & Tubes, Hastelloy Alloy C276 Pipes & Tubes Price, UNS N06022 Hastelloy Pipes & Tubes, UNS N10276 Hastelloy Alloy Pipes & Tubes

Hastelloy is a high-performance nickel-based alloy that is known for its excellent corrosion resistance, strength, and durability. Hastelloy is commonly used in applications where harsh conditions exist, including high-temperature, high-pressure, and highly corrosive environments. Hastelloy pipe is a popular choice for many industries, including chemical processing, oil and gas, power generation, and aerospace. In this article, we will discuss the material grades, standards, process, chemical composition, properties, application, and more about Hastelloy pipes.

Hastelloy Pipes are manufactured in accordance with various international standards such as ASTM, ASME, and API. These standards outline the specific requirements for the manufacture, testing, and inspection of the pipes to ensure their quality and durability.

Some of the common standards for Hastelloy pipes are:

• ASTM B622/B619/B626/B775/B829

• ASME SB622/SB619/SB626/SB775/SB829

C276/C22/B2 Hastelloy Pipes & Tubes Specification :

Specifications

ASTM B622 ASME SB622 / ASTM B619 ASME SB619

Dimensions

ASTM, ASME, and API

Size

1/2″NB TO 12 "NB IN

Specialized in

Large Diameter Size

Schedule

SCH5, SCH10, SCH20, SCH30, SCH40, STD, SCH80, SCH 80S, SCH60, SCH80, SCH120, SCH140, SCH160, SCH XXS, SCH XS

Type

Seamless / ERW / Welded / Fabricated

Form

Seamless Pipes, ERW Pipe, EFW, Pipe, Seamless Tube, ERW Tube, Square Pipe.

Length

Single Random, Double Random & Required Length.

End

Plain End, Beveled End, Treaded

Hastelloy C276/C22/B2 Pipes & Tubes Chemical Composition

Grade

Ni

C

Mo

Mn

Si

Fe

P

S

Co

Cr

Hastelloy C276

Balance

0.01 max

15 – 17

1.0 max

0.08 max

4 – 7

0.04 max

0.03 max

2.5 max

14.5 – 16.5

Hastelloy C22

Balance

0.010 max

12.5 – 14.5

0.50 max

0.08 max

2 – 6

0.02 max

0.02 max

2.5 max

20 – 22.5

Hastelloy B2

Balance

0.02 max

26.0-30.0

1.0 max

0.10 max

2.0 max

0.040 max

0.030 max

1.0 max

1.0 max

Mechanical Properties of C276/C22/B2 Hastelloy Pipes & Tubes

Grade

Density

Melting Point

Yield Strength (0.2%Offset)

Tensile Strength

Elongation

Hastelloy C276

8.89 g/cm3

1370 °C (2500 °F)

Psi – 52,000, MPa – 355

Psi – 1,15,000, MPa – 790

40 %

Hastelloy C22

8.69 g/cm3

1399 °C (2550 °F)

Psi – 45000, MPa – 310

Psi – 1,00,000, MPa – 690

45 %

Hastelloy B2

9.2 g/cm3

1370 °C (2500 °F)

Psi – 51,000, MPa – 350

Psi -1,10,000, MPa -760

40 %

Equivalent Grades of Hastelloy C276/C22/B2 Pipes & Tubes

STANDARD

UNS

WERKSTOFF NR.

AFNOR

EN

JIS

OR

GOST

Hastelloy C276

N10276

2.4819

–

NiMo16Cr15W

NW 0276

ЭП760

ХН65МВУ

Hastelloy C22

N06022

2.4602

–

NiCr21Mo14W

NW 6022

–

–

Hastelloy B2

N10276

2.4617

–

–

–

–

–

The manufacturing process for Hastelloy pipes according to ASME B36.10

1. Melting: The raw materials are melted in a furnace to form a molten alloy.

2. Casting: The molten alloy is poured into a mold to form a solid billet.

3. Rolling: The billet is then rolled into a tube shape using a rolling mill.

4. Heat Treatment: The tube is then heat-treated to ensure its desired properties.

5. Finishing: The tube is then cut to the required length, deburred, and cleaned.

Hastelloy pipes are used in a variety of industries and applications, including:

• Chemical processing and petrochemical industries

• Oil & Gas exploration and refining

• Aerospace and defense industries

• Power generation industry

• Pollution control and waste treatment systems

• Marine and offshore industries

Send Inquiry

Copyright © 2024-2025 TSINGSHAN INDUSTRY(TIANJIN)CO.,LTD All Rights Reserved. 备案中... Privacy Policy

Home

Home Tel

Tel Email

Email Mobile phone

Mobile phone