- Categories

-

- Carbon Steel

- »Seamless Steel Pipe

- »02API Line pipe

- »03Weld Steel Pipe

- »04_Square pipe

- »05_Ductile Iron pipe

- »06_Carbon Steel Sheet

- »07_Carbon Steel Coil/Strip

- »08_Steel Bar

- »09_Rebar

- »Steel Profile

- Galvanized Steel

- »Galvanized Steel Pipe

- »Galvanized Steel Sheet

- »Galvanized Steel Coil

- »Galvalume/Aluzinc Steel Coil

- »PPGI/PPGL

- »Corrugated Roofing Sheet

- »Galvanized Steel Wire

- »Galvanized Steel Profile

- Latest Products

-

-

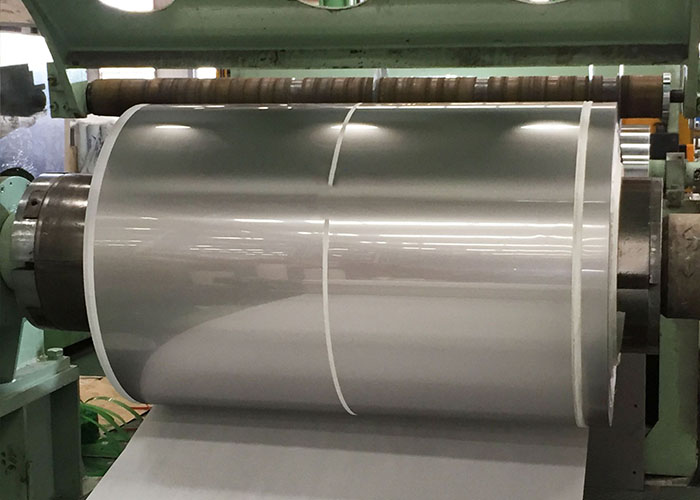

PPGI/PPGL

-

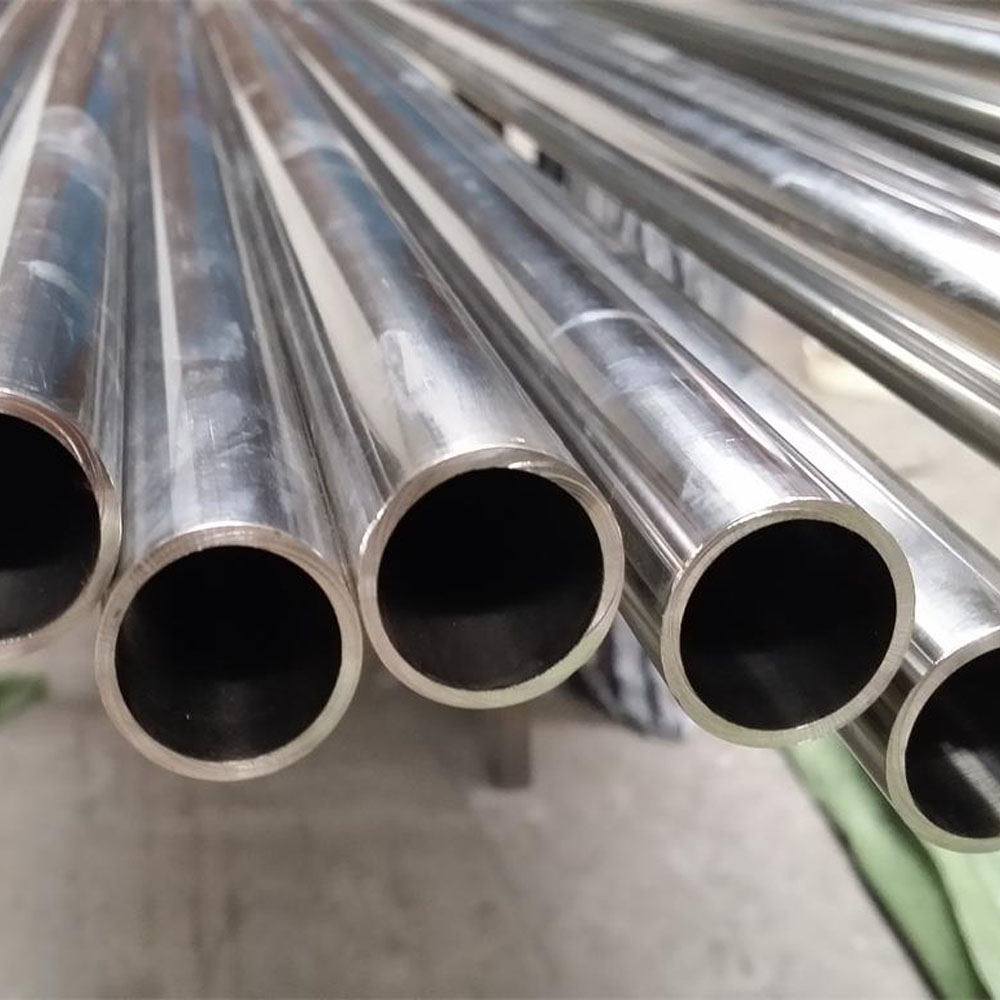

ASTM A321 TP321 seamless welded pipe and tube

-

ASTM B677 UNS NO8904 904L Pipe Tube

-

Hastelloy C-22 ASTM B474 UNS N06022 Alloy C-22 DIN 2.4602 EFW Welded Pipe

-

Duplex Steel N08904 Plate Sheet

-

Inconel 690 2.4642 Plate Sheet

-

ASTM B162 ASME SB162 UNS N02201 Alloy Steel Plate Sheet

-

ASTM A276 S30400 Round Bar

-

- Contact Us

-

Tel: 0086-17695531343

WhatsApp: 022-26819651

E-mail: sales@tsingshan-scaffold.com

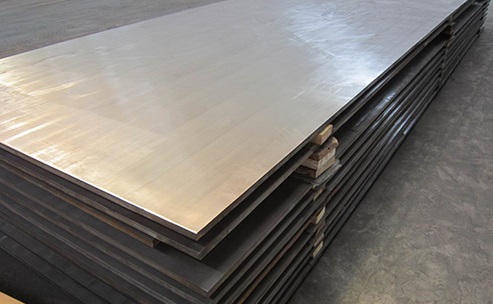

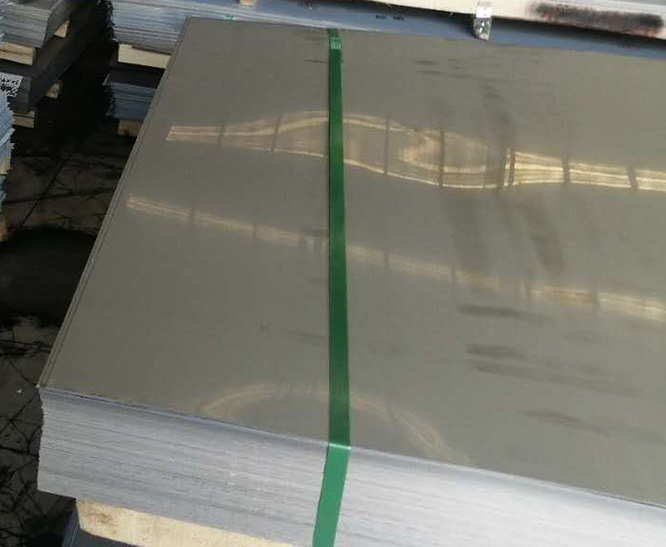

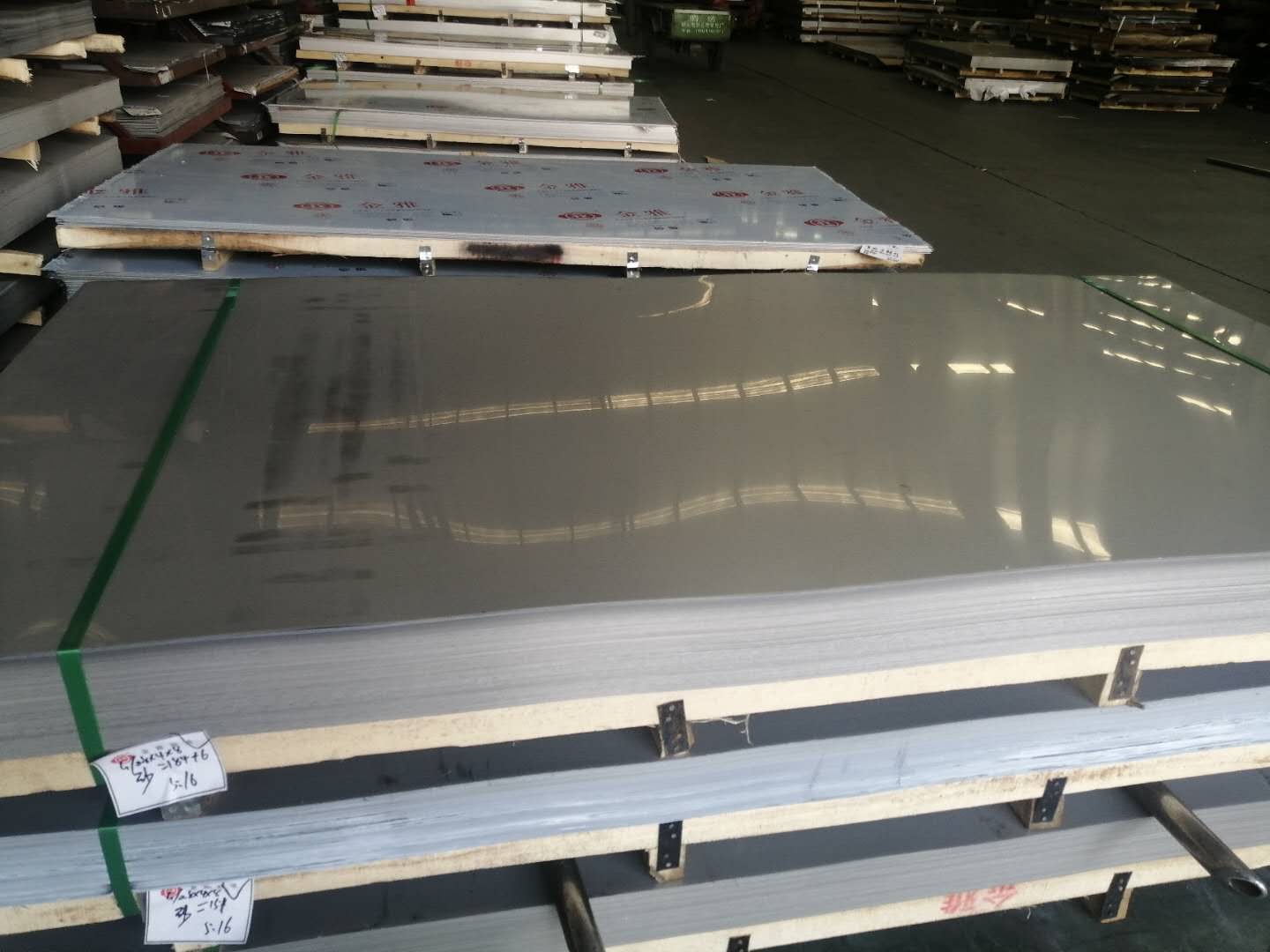

Stainless Steel 254SMO Plate

-

Type: Plate, Sheet, Strip, Coil

Length: 0-12m

Width: 0-2500mm

Thickness: 0.3-1200mm

Process: Hot/Cold Rolled

Surface: 1,2D,2B BA,3,4,6,7

Stainless Steel 254SMO Plate, 254 SMO Sheet, UNS S31254 Plate, 1.4547 Plate, 254 SMO Hot Rolled Plate, UNS S31254 Cold Rolled Plate.

Alloy 254 SMO Plate is a very high end, molybdenum and nitrogen alloyed super austenitic stainless steel with low carbon content. Stainless Steel 254SMO Plate demonstrates outstanding resistance to pitting, crevice corrosion stress cracking, and corrosion fatigue uniform corrosion. 254 SMO Plate, also known as UNS S31254 Plate or 1.4547 Plate, is a high-alloy austenitic stainless steel with excellent corrosion resistance. UNS S31254 Plate has a corrosive resistance level that is twice that of 300 series stainless steel and is extremely resistant to pitting and crevice corrosion. Due to its superior resistance to seawater, 1.4547 Plate is a popular choice for maritime applications.

Stainless Steel 254SMO Plate is made with a unique combination of metals

such as chromium, molybdenum, and nitrogen that gives 254 SMO Sheet

unparalleled strength and durability. The high levels of these metals

make 1.4547 Plate ideal for use in harsh environments such as chemical

processing, oil and gas, and petrochemical industries. The alloy is also

resistant to high temperatures and can withstand up to 1000°C without

losing its shape or mechanical properties.

1. Difference between 254 SMO Sheet, Plate & Foil

Thickness less than 0.15mm is called a ASME SA 240 S31254 Foil.

Thickness greater than 0.15 mm and less than 6.35mm is called a Alloy 254 6mo Sheet.

Thickness greater than 6.35 mm is called a UNS S31254 F44 Plate.

2. SMO 254 Sheet, Plate & Coil Specifications

Standards

UNS: S31254

EN Number: 1.4547

EN Name: X1CrNiMoCuN20-18-7

W.Nr.: 1.4529**

SS: 2378*

AFNOR: Z1 CNDU 20.18.06AZ*

Specifications | ASTM A240 / ASME SA240 |

Thickness | 4mm-100mm |

Width | 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc |

Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc |

Surface | 2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, checkered, embossed, hair line, sand |

Finish | Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated) |

Form | Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Perforated Sheet, Chequered Plate, Strip, Flats, Blank (Circle), Ring (Flange) etc. |

Specialized in | SMO 254 Plates |

3.Applications

254 SMO is used in the following applications:

Equipment for handling of seawater, such as, seawater cooling, cooling water pipes, ballast water systems, firefighting systems etc.

Hydraulic and instrumention tubing

Equipment in pulp bleaching plants

Components in gas cleaning systems

Tanks and pipelines for chemicals with high halide contents

Avoid abrasion against copper/copper alloys or other similar metals which, if present in metallic form, can cause cracks during subsequent welding, hot processing or heat treatment.

Machining

254 SMO is a high alloyed austenitic stainless steel and thus tougher inserts in metal cutting are needed than is the case for lower alloyed austenitic grades. When machining 254 SMO considerably lower cutting speeds are recommended compared to the grades Sanmac 304/304L and Sanmac 316/316L, which have improved machinability.

4. Documents

Documentation

• Commercial Invoice which includes HS Code

• Packing List including net weight and gross weight, number of boxes, Marks and Numbers

• Certificate of Origin legalized/attested by Chamber of Commerce or Embassy

• Fumigation Certificates

• Raw Material Test Reports

• Material Traceability Records

• Quality Assurance Plan (QAP)

• Heat Treatment Charts

• Test Certificates certifying NACE MR0103, NACE MR0175

• Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2

• Guarantee Letter

• NABL approved Laboratory Test Reports

• Welding Procedure Specification/Procedure Qualification Record, WPS/PQR

• Form A for the purposes of the Generalized System of Preferences (GSP)

SMO 254 Plate, Sheet & Coil Chemical Composition

Grade | Ni | Cr | Mo | Cu | N | C | Mn | Si | P | S |

SMO 254 | 17.5-18.5 | 19.5-20.5 | 6-6.5 | 0.5-1.0 | 0.18-0.22 | 0.02 | 1.0 | 0.08 | 0.03 | 0.01 |

SMO 254 Sheets, Plates & Coils Mechanical Properties

Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

8.0 g/cm3 | 1320-1390 ℃ | 650 | 300 | 35 % |

Equivalent Grades for 254 SMO Sheets & Plates

STANDARD | WERKSTOFF NR. | UNS | SIS | AFNOR | EN |

SMO 254 | 1.4547 | S31254 | 2378 | Z1 CNDU 20.18.06Az | X1CrNiMoCuN20-18-7 |

5. 254 SMO Plate Physical Properties:

Grade: | Alloy 254 |

Density | 8.0 kg/dm3 |

Modulus of Elasticity | 195 GPa |

Linear Expansion | 16.5 X10-6/oC |

Thermal Conductivity | 14 w/moC |

Thermal Capacity | 500 J/kgoC |

Electrical Resitivity | 0.85 μΩm |

Send Inquiry

Copyright © 2024-2025 TSINGSHAN INDUSTRY(TIANJIN)CO.,LTD All Rights Reserved. 备案中... Privacy Policy

Home

Home Tel

Tel Email

Email Mobile phone

Mobile phone