- Categories

-

- Carbon Steel

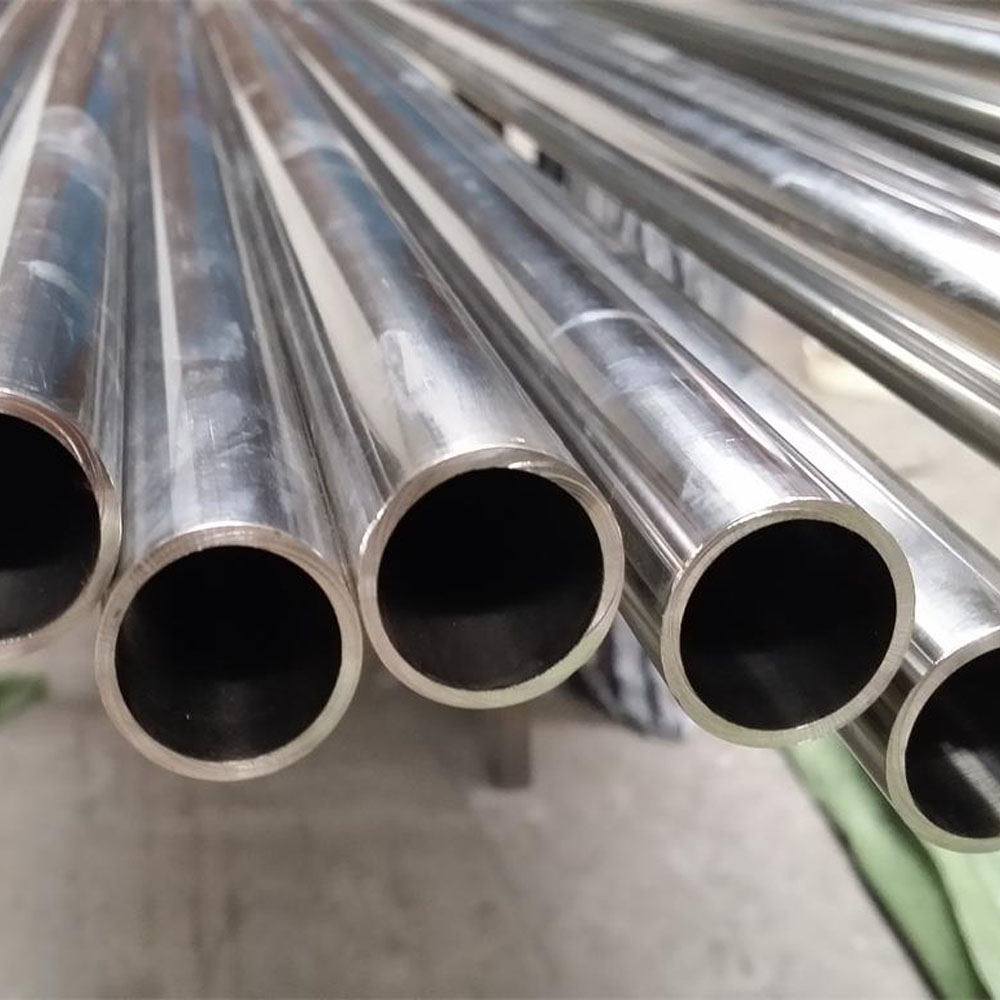

- »Seamless Steel Pipe

- »02API Line pipe

- »03Weld Steel Pipe

- »04_Square pipe

- »05_Ductile Iron pipe

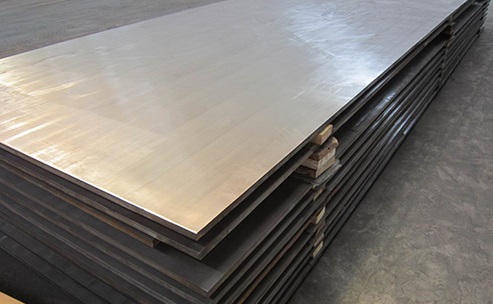

- »06_Carbon Steel Sheet

- »07_Carbon Steel Coil/Strip

- »08_Steel Bar

- »09_Rebar

- »Steel Profile

- Galvanized Steel

- »Galvanized Steel Pipe

- »Galvanized Steel Sheet

- »Galvanized Steel Coil

- »Galvalume/Aluzinc Steel Coil

- »PPGI/PPGL

- »Corrugated Roofing Sheet

- »Galvanized Steel Wire

- »Galvanized Steel Profile

- Latest Products

-

-

PPGI/PPGL

-

ASTM A321 TP321 seamless welded pipe and tube

-

ASTM B677 UNS NO8904 904L Pipe Tube

-

Hastelloy C-22 ASTM B474 UNS N06022 Alloy C-22 DIN 2.4602 EFW Welded Pipe

-

Duplex Steel N08904 Plate Sheet

-

Inconel 690 2.4642 Plate Sheet

-

ASTM B162 ASME SB162 UNS N02201 Alloy Steel Plate Sheet

-

ASTM A276 S30400 Round Bar

-

- Contact Us

-

Tel: 0086-17695531343

WhatsApp: 022-26819651

E-mail: sales@tsingshan-scaffold.com

Alloy 625 Round Bar

-

Standard : EN, DIN, JIS, ASTM, BS, ASME, AISI Range : 3.17 MM TO 350 MM DIA Length : 1 to 6 Meters, Custom Cut Lengths Round Bars : Outside Diameter in the range of 4mm to 500mm Bright Bars : Outside Diameter in the range of 4mm to 100mm Hex Bars : 18mm – 57mm (11/16″ to 2-3/4″) Square Bars : 18mm – 47mm (11/16″ to 1-3/4″) Form : Round, Square, Hex (A/F), Rectangle, Flat, Billet, Ingot, Forging Etc.

Inconel625 is a nickel-based superalloy with excellent resistance to oxidation and corrosion, in conditions ranging from jet engine propulsion systems to chemical processing of oxidizing and reducing acids.

The nickel-chromium matrix of Inconel 625 is reinforced by the addition of molybdenum and niobium, which is alloyed through solid solution strengthening, and this allows it to maintain high strength and toughness at temperatures ranging from cryogenic up to 2000°F (1093°C). It is non-magnetic, austenitic, and displays high tensile strength, fabricability, and brazeability.

Inconel 625 Round Bar Equivalent Grades :

| STANDARD | WERKSTOFF NR. | UNS | GOST | AFNOR | JIS | BS | EN | OR |

| Inconel 625 | 2.4856 | N06625 | 75 | NC22DNB4M | NCF 625 | NA 21 | NiCr22Mo9Nb | 602 |

Chemical Composition of Alloy 625 Rods

Grade Ni Cr Fe C Mn Si Mo Co Al Ti Nb + Ta P S Inconel 625 58.0 min 20.0 – 23.0 5.0 max 0.10 max 0.50 max 0.50 max 8.0 – 10.0 1.0 max 0.40 max 0.40 max 3.15 – 4.15 0.015 max 0.015 max

| Grade | Ni | Cr | Fe | C | Mn | Si | Mo | Co | Al | Ti | Nb + Ta | P | S |

| Inconel 625 | 58.0 min | 20.0 – 23.0 | 5.0 max | 0.10 max | 0.50 max | 0.50 max | 8.0 – 10.0 | 1.0 max | 0.40 max | 0.40 max | 3.15 – 4.15 | 0.015 max | 0.015 max |

Mechanical Properties of Inconel 625 Bars

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.4 g/cm3 | 1350 °C (2460 °F) | Psi – 135,000 , MPa – 930 | Psi – 75,000 , MPa – 517 | 42.5 % |

Send Inquiry

Copyright © 2024-2025 TSINGSHAN INDUSTRY(TIANJIN)CO.,LTD All Rights Reserved. 备案中... Privacy Policy

Home

Home Tel

Tel Email

Email Mobile phone

Mobile phone