Your Location:

HOME >> PRODUCTS >> Stainless Steel >> Stainless Steel Bar>>Alloy 718 Round Bar

- Categories

-

- Carbon Steel

- »Seamless Steel Pipe

- »02API Line pipe

- »03Weld Steel Pipe

- »04_Square pipe

- »05_Ductile Iron pipe

- »06_Carbon Steel Sheet

- »07_Carbon Steel Coil/Strip

- »08_Steel Bar

- »09_Rebar

- »Steel Profile

- Galvanized Steel

- »Galvanized Steel Pipe

- »Galvanized Steel Sheet

- »Galvanized Steel Coil

- »Galvalume/Aluzinc Steel Coil

- »PPGI/PPGL

- »Corrugated Roofing Sheet

- »Galvanized Steel Wire

- »Galvanized Steel Profile

- Latest Products

-

-

PPGI/PPGL

-

ASTM A321 TP321 seamless welded pipe and tube

-

ASTM B677 UNS NO8904 904L Pipe Tube

-

Hastelloy C-22 ASTM B474 UNS N06022 Alloy C-22 DIN 2.4602 EFW Welded Pipe

-

Duplex Steel N08904 Plate Sheet

-

Inconel 690 2.4642 Plate Sheet

-

ASTM B162 ASME SB162 UNS N02201 Alloy Steel Plate Sheet

-

ASTM A276 S30400 Round Bar

-

- Contact Us

-

Tel: 0086-17695531343

WhatsApp: 022-26819651

E-mail: sales@tsingshan-scaffold.com

Alloy 718 Round Bar

-

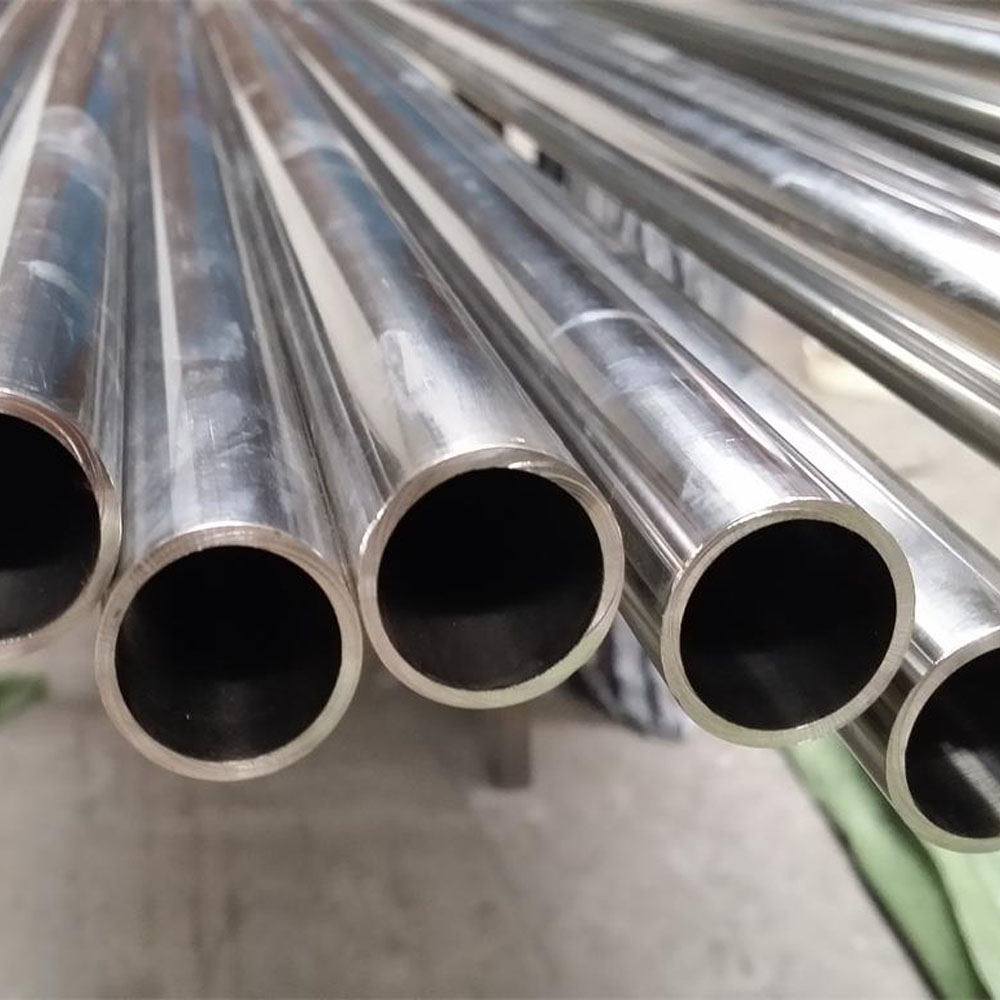

Standard : EN, DIN, JIS, ASTM, BS, ASME, AISI Range : 3.17 MM TO 350 MM DIA Length : 1 to 6 Meters, Custom Cut Lengths Round Bars : Outside Diameter in the range of 4mm to 500mm Bright Bars : Outside Diameter in the range of 4mm to 100mm Hex Bars : 18mm – 57mm (11/16″ to 2-3/4″) Square Bars : 18mm – 47mm (11/16″ to 1-3/4″) Form : Round, Square, Hex (A/F), Rectangle, Flat, Billet, Ingot, Forging Etc.

| Element | Percent by Weight | |

|---|---|---|

| C | Carbon | 0.08 maximum |

| Mn | Manganese | 0.35 maximum |

| P | Phosphorus | 0.015 maximum |

| S | Sulfur | 0.015 maximum |

| Si | Silicon | 0.35 maximum |

| Cr | Chromium | 17.00 - 21.00 |

| Ni | Nickel | 50.00 - 55.00 |

| Mo | Molybdenum | 2.80 - 3.30 |

| Nb | Columbium | 4.75 - 5.50 |

| Ti | Titanium | 0.65 - 1.15 |

| Al | Aluminum | 0.20 - 0.80 |

| Co | Cobalt | 1.00 maximum |

| B | Boron | 0.006 maximum |

| Cu | Copper | 0.30 maximum |

| Ta | Tantalum | 0.05 maximum |

| Fe | Iron | Balance |

Alloy 718 Physical Properties

| Annealed Condition | Aged Condition | |

|---|---|---|

| Density | 0.296 lb./in3 (8.19 g/cm3) | 0.297 lb./in3 (8.22 g/cm3) |

| Specific Gravity | 8.19 | 8.22 |

| Temperature Range | Coefficients | ||

|---|---|---|---|

| °C | °F | W/m·K | Btu/(hr/ft²/in/°F) |

| 0-100 | 32-212 | 6.5 | 11.2 |

Electrical Resistivity at 68°F (20°C)

Annealed: 127 microhm-cm

Aged: 121 microhm-cm

Mechanical Properties and Yield Strength of Alloy 718

| Product | Yield Strength Max (0.2% Offset) | Ultimate Tensile Strength Max | Elongation (% in 2") |

|---|---|---|---|

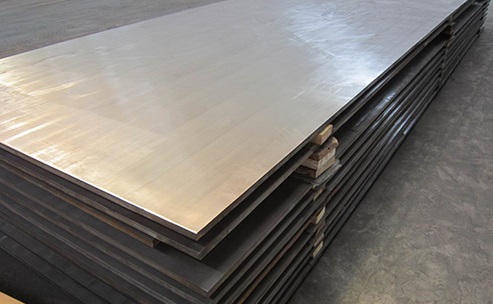

| Sheet and Strip | 80,000 psi (550 MPa) | 14,000 (965 MPa) | 30 (min) |

| Plate | 105,000 psi (725 MPa) | 150,000 (1,035 MPa) | 30 (min) |

| Yield Strength Min (0.2% Offset) | Ultimate Tensile Strength Min | Elongation (% in 2") |

|---|---|---|

| 150,000 (1,035 MPa) | 180,000 (1,240 MPa) | 12 (min) |

Previous:Alloy 825 Round Bar

Next:Alloy 625 Round Bar

Send Inquiry

Copyright © 2024-2025 TSINGSHAN INDUSTRY(TIANJIN)CO.,LTD All Rights Reserved. 备案中... Privacy Policy

Home

Home Tel

Tel Email

Email Mobile phone

Mobile phone