- Categories

-

- Carbon Steel

- »Seamless Steel Pipe

- »02API Line pipe

- »03Weld Steel Pipe

- »04_Square pipe

- »05_Ductile Iron pipe

- »06_Carbon Steel Sheet

- »07_Carbon Steel Coil/Strip

- »08_Steel Bar

- »09_Rebar

- »Steel Profile

- Galvanized Steel

- »Galvanized Steel Pipe

- »Galvanized Steel Sheet

- »Galvanized Steel Coil

- »Galvalume/Aluzinc Steel Coil

- »PPGI/PPGL

- »Corrugated Roofing Sheet

- »Galvanized Steel Wire

- »Galvanized Steel Profile

- Latest Products

-

-

PPGI/PPGL

-

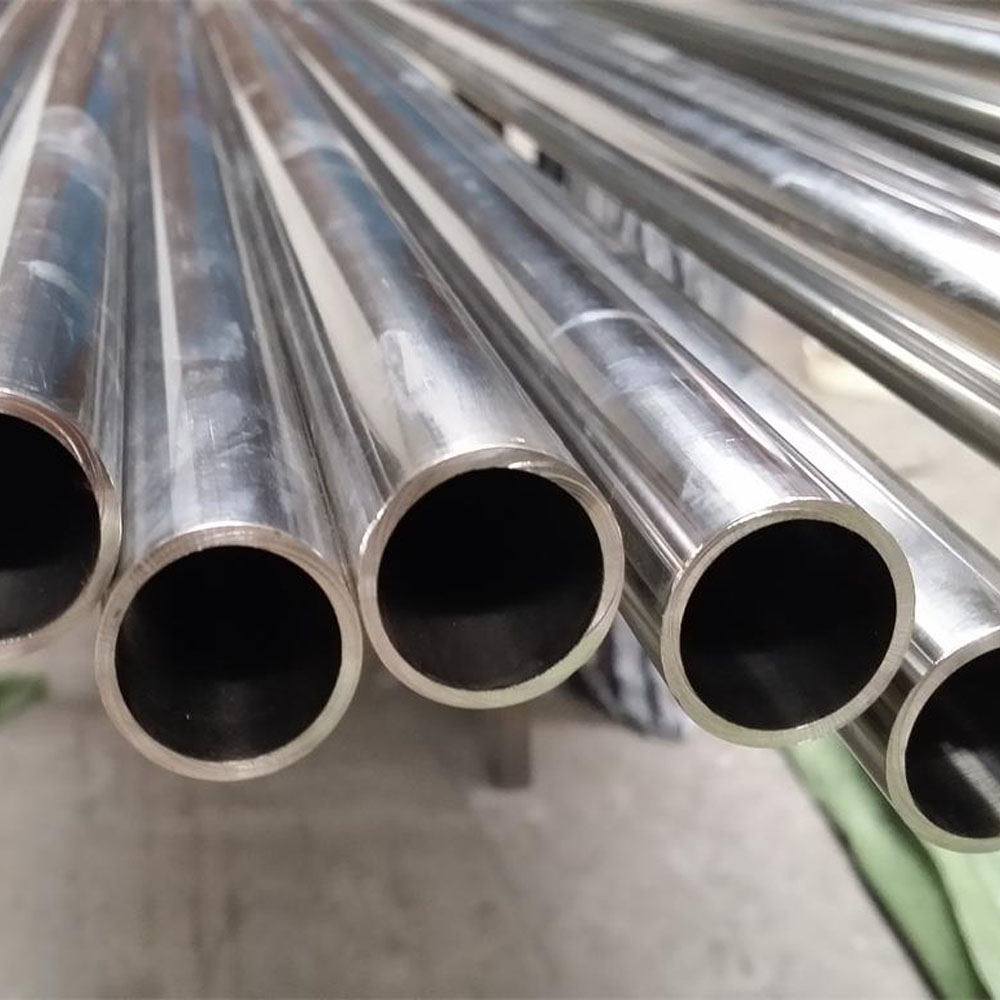

ASTM A321 TP321 seamless welded pipe and tube

-

ASTM B677 UNS NO8904 904L Pipe Tube

-

Hastelloy C-22 ASTM B474 UNS N06022 Alloy C-22 DIN 2.4602 EFW Welded Pipe

-

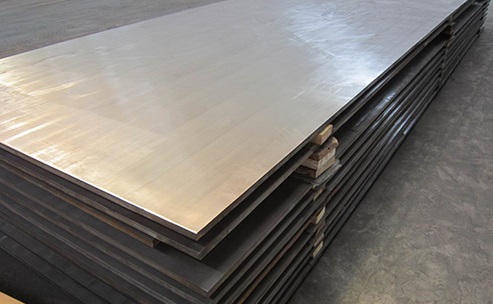

Duplex Steel N08904 Plate Sheet

-

Inconel 690 2.4642 Plate Sheet

-

ASTM B162 ASME SB162 UNS N02201 Alloy Steel Plate Sheet

-

ASTM A276 S30400 Round Bar

-

- Contact Us

-

Tel: 0086-17695531343

WhatsApp: 022-26819651

E-mail: sales@tsingshan-scaffold.com

Hastelloy B3 Rod

-

Hastelloy B3 is a molybdenum based nickel alloy with higher structural stability at higher temperatures than Hastelloy B2 alloy. Also often referred as Hastelloy B3; It has excellent resistance to pitting, corrosion and stress corrosion crackiing in chloride-bearing solutions. Hastelloy B3 can withstand sulphuric, acetic, formic and phosphoric acids. Further it has ability to sustain well in fluoride-bearing media, which results in damage to zirconium alloys.

Hastelloy B3

Chemical Properties | |||||||||||

C | Mn | P | S | Si | Cr | Mo | Ni | Cu | V | Cb | Ti |

0.01 Max | 3.0 Max | 0.030 Max | 0.010 Max | 0.10 Max | 1.0-3.0 | 27.0-32.0 | 65.0 Min | 0.20 Max | 0.20 Max | 0.20 Max | 0.20 Max |

Al | W | Co | Ta | Fe | Zr | Ni+Mo | |||||

0.50 Max | 3.0 Max | 3.0 Max | 0.20 Max | 1.0-3.0 | 0.10 Max | 94.0-98.0 | |||||

Mechanical Properties | ||

Yeild strength | Tensile strength | Elongation |

Min 0.2% Mpa | Min Mpa | Min % |

350 | 760 | 40 |

Physical Properties | |||||

Density | Elastic Modulus | Mean Coefficient of Thermal | Thermal Conductivity | Specific Heat | Electrical Resistivity |

(Kg/m 3 ) | (Gpa) | Expansion( μ m/m/°C) | (W/m.K) | 0-100°C | (n Ω .m) |

9.22 | 216 | 5.7 | 11.2 | 373 | 53.8 |

Equivalent Designation | |||||||

ASTM/ASME | AISI | UNS | British Standard | Werkstoff No. | En Name | Swedish(SS) | JIS(SUS) |

|

| N10675 | – | – | – | – | |

Send Inquiry

Copyright © 2024-2025 TSINGSHAN INDUSTRY(TIANJIN)CO.,LTD All Rights Reserved. 备案中... Privacy Policy

Home

Home Tel

Tel Email

Email Mobile phone

Mobile phone