- Categories

-

- Carbon Steel

- »Seamless Steel Pipe

- »02API Line pipe

- »03Weld Steel Pipe

- »04_Square pipe

- »05_Ductile Iron pipe

- »06_Carbon Steel Sheet

- »07_Carbon Steel Coil/Strip

- »08_Steel Bar

- »09_Rebar

- »Steel Profile

- Galvanized Steel

- »Galvanized Steel Pipe

- »Galvanized Steel Sheet

- »Galvanized Steel Coil

- »Galvalume/Aluzinc Steel Coil

- »PPGI/PPGL

- »Corrugated Roofing Sheet

- »Galvanized Steel Wire

- »Galvanized Steel Profile

- Latest Products

-

-

PPGI/PPGL

-

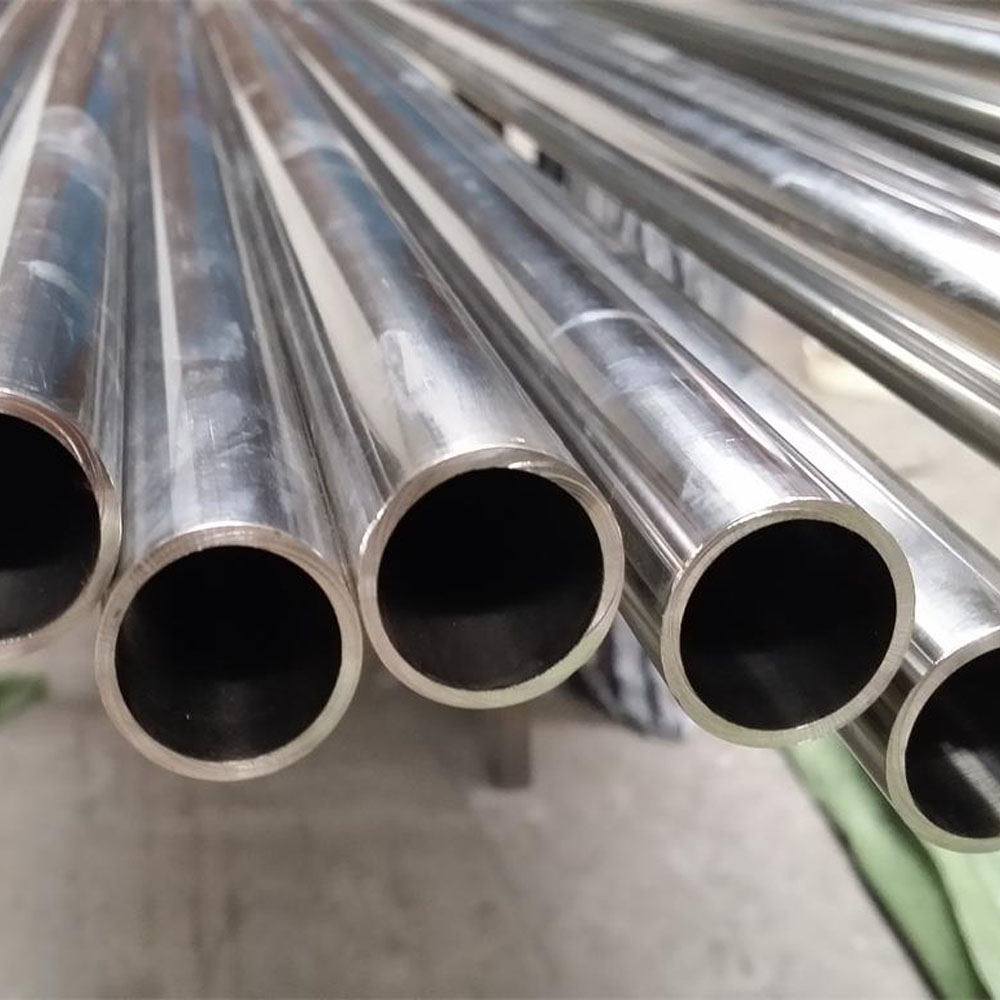

ASTM A321 TP321 seamless welded pipe and tube

-

ASTM B677 UNS NO8904 904L Pipe Tube

-

Hastelloy C-22 ASTM B474 UNS N06022 Alloy C-22 DIN 2.4602 EFW Welded Pipe

-

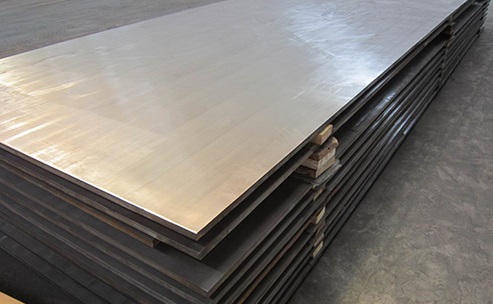

Duplex Steel N08904 Plate Sheet

-

Inconel 690 2.4642 Plate Sheet

-

ASTM B162 ASME SB162 UNS N02201 Alloy Steel Plate Sheet

-

ASTM A276 S30400 Round Bar

-

- Contact Us

-

Tel: 0086-17695531343

WhatsApp: 022-26819651

E-mail: sales@tsingshan-scaffold.com

ASTM B446 Inconel 625 Alloy 625 N06625 Billet

-

Bright Black Surface Nickel Alloy ASTM B446 Inconel 625 Alloy 625 N06625 Billet price per kg

INCONEL ALLOY 625

UNS Number N06625

Other common names: Alloy 625

Inconel

625 is a corrosion and oxidation resistant nickel alloy that is used

both for its high strength and outstanding aqueous corrosion resistance.

Its outstanding strength and toughness is due to the addition of

niobium which acts with the molybdenum to stiffen the alloy’s matrix.

Alloy 625 has excellent fatigue strength and stress-corrosion cracking

resistance to chloride ions. This nickel alloy has excellent weldability

and is frequently used to weld AL-6XN. This alloy resists a wide range

of severely corrosive environments and is especially resistant to

pitting and crevice corrosion. Some typical applications Inconel 625 is

used in are chemical processing, aerospace and marine engineering,

pollution-control equipment, and nuclear reactors.

In what form is Inconel 625 available?

• Sheet

• Plate

• Bar

• Pipe & Tube (welded & seamless)

• Wire

What are the characteristics of Inconel 625?

• High creep-rupture strength

• Oxidation resistant to 1800° F

• Seawater pitting and crevice corrosion resistant

• Immune to chloride ion stress corrosion cracking

• Non-magnetic

Chemical Composition, %

Cr Ni Mo Co + Nb Ta Al Ti C 20.00-30.00 Remainder 8.0-10.0 1.0 max 3.15-4.15 .40 max .40 max .10 max

Fe Mn Si P S 5.0 max .50 max .50 max .015 max .015 max

Send Inquiry

Copyright © 2024-2025 TSINGSHAN INDUSTRY(TIANJIN)CO.,LTD All Rights Reserved. 备案中... Privacy Policy

Home

Home Tel

Tel Email

Email Mobile phone

Mobile phone